The south west of England is a hotspot for cereal diseases, but has the potential for some of the highest yields in the UK. CPM joins Real Results grower Mike Hambly as he reviews the past two years’ trials.

This part of the world suffers from septoria isolates as aggressive as those you’d find in Ireland.

By Tom Allen-Stevens

Mike Hambly describes himself as a “careful Cornishman”. He can’t deny he’s drawn by the attraction of big yields, but keeps his focus firmly on the profit these must deliver.

“The thing that gives me a kick at the end of the day is a full barn – that’s the ultimate satisfaction. But I’m proudly Cornish, and it must be in our Celtic nature to scrutinise costs closely, so the way we farm is aimed squarely at delivering a healthy margin,” he says.

Farming in South East Cornwall near Callington, Mike runs and operates the Westcott Farm Partnership with his wife Anne. There’s 195ha of clay loam soils with a four-course rotation of winter wheat, winter oats, winter barley and oilseed rape. This is run alongside a beef enterprise that comprises a two-year system to graze the farm’s permanent pasture while steers from an intensive housed herd are sold at 13 months to “walk the barley off the farm”.

For Mike, weather is the biggest challenge of his arable system. “Our average rainfall used to be 125cm a year, but it’s more like 150cm now, while it tipped 200cm in 2012. While some may look at rainfall as a blessing, for us the wet conditions are a limitation and govern much of how we grow the crops on land that all lies on the side of a hill.”

It was a determination to make the most of this resource that led Mike to join the Yield Enhancement Network (YEN). “The NFU was a sponsor of YEN and that’s how I first became involved during my term as national crops board chairman. I remember the first meeting I went to at which Roger Sylvester-Bradley displayed a map that showed, with the sunlight and rainfall we get in the South West, that we should be achieving wheat yields of 22t/ha. I thought I must be the biggest failure, but decided to see what I could do to improve ours, that average 10.5t/ha.”

It’s also brought Mike into BASF’s Real Results Circle – 50 farmers working together with the manufacturer conducting farm-scale trials using their own kit and management systems. The trials are focused on achieving the optimum returns from using new crop technology, and since 2018 this has focused chiefly on the new fungicide Revystar XE (fluxapyroxad+ mefentrifluconazole).

The trials are assessed using ADAS’ Agronomics tool, which delivers statistical confidence to tramline or field-wide treatment comparisons. Led by the farmers themselves, they share their experiences and learn from each other to ensure results achieved are transparent, relevant and ‘real’.

Mike’s joined by BASF regional agronomy manager Richard Guest in a Zoom meeting to discuss the results and the experiences of the past two years’ trials. “2018 was our first year for both Real Results and YEN, and we’ve been using Revystar on the tramline comparisons for the past two harvests, which last year was in barley,” recalls Mike.

“While it was the yield appeal of YEN that drew me in, the real benefit is in the analysis you get. I’m not sure any arable farmer would find something that gets better value for money than the soil, grain and growing crop analyses YEN gives you. The ability to benchmark these is incredibly valuable, especially on the nutrient side.”

One area the results have flagged up this year is that manganese isn’t getting into his grain – a deficiency he aims to resolve. The trials have also highlighted another limitation that’s a common problem in Mike’s part of the world – field size.

“We’ve realised we’re getting considerably lower yields off the headlands – these are excluded from the YEN and Real Results analyses. It’s a problem for us as the average field size is just 4ha, which means headlands cover around a third of the farm.”

Mike uses a 2.5m Sumo Trio in front of a 3m Väderstad Rapid drill. The plough’s retained and used rotationally in front of the oats to minimise volunteers. “I love the Rapid and can drill up to 40ha of OSR per day. But these past couple of years it’s been the Achilles heel in the system and many growers in this area have got on better running a power harrow combination drill immediately behind the plough.”

He has fewer doubts over variety choice, however, with genetics used as part of the armoury against septoria. Graham is the main wheat variety grown and it was the one included in the 2019 Real Results trial. This produced an adjusted yield of 13.1t/ha in the Revystar-treated area against a result in the farm standard area of 13.0t/ha. The entire field yielded 11.36t/ha against a farm average of 10.62t/ha.

“Graham’s a stalwart in the South West. It yielded exceptionally well for us in 2019 and has performed well in local trials in 2020. We now have Graham and KWS Extase in the ground, and the big question for 2021 is how much we should reduce fungicide spend between the varieties, given their differing septoria resistance scores.

“I’d be very cautious of pulling back, bearing in mind the septoria pressure we face. We’ve lost CTL, and I view Extase as making up its replacement, but that doesn’t mean you drop back on the rest of the fungicide programme as that would put its disease resistance under pressure. What’s more, independent data suggests you get payback from a good fungicide programme even on varieties with good disease scores.”

Richard agrees. “This part of the world suffers from septoria isolates as aggressive as those you’d find in Ireland, and the continued slip in efficacy of most fungicides makes disease management a challenge. With no CTL, keeping a crop protected will come down to the strength and longevity of the product used. Revystar performs extremely well here, and has far superior control of difficult strains.”

Mike notes his trial delivered a yield benefit for Revysol of 0.1t/ha. “It probably wasn’t the season to tease out the benefits in Cornwall. But I visited the trials in Ireland and you could see there was a massive difference between the treatments.

“The one that sticks in my mind is the trial that showed the kickback you get from Revystar if your T2 spray is delayed. Not every day is a perfect spray day, and the BASF CuraCrop latent septoria testing we take part in shows there’s disease in the crop even when you can’t see it.”

This is an area where Mike’s keen to get a more informed picture of the disease threat so he can tailor his fungicide programme accordingly and now he has two weather stations on the farm that should provide better information on rainfall during the season. Richard notes that xarvio Spray Timer gives very accurate forecasts on disease risk to a specific crop and the best timing to spray.

“Better foresight would be a wonderful thing to have,” agrees Mike. “From what we have in the ground things are looking more promising for 2021. The Cornishman in me will continue to be careful with how we spend on it, but I’m hopeful we can manage the crop to a really satisfying barnful.”

Encouraging result in a difficult year

Last year was an extraordinary one for many different reasons, and the winter barley crop that became the focus of Mike’s Real Results trials was one of the year’s many unusual outcomes.

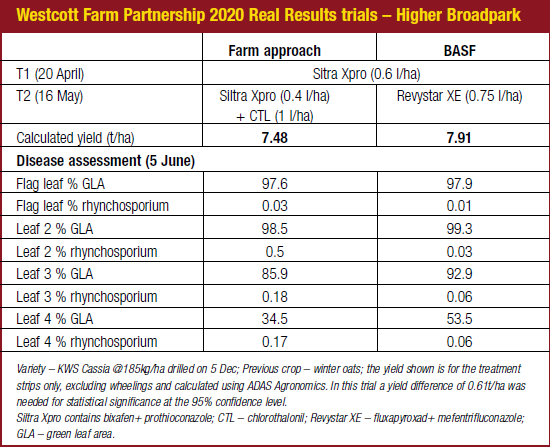

“I felt like an imposter all the way through with this crop as one of the YEN entries. At times it was soul-destroying how the weather punished it, but in the end, I was really pleasantly surprised at the results we achieved, especially in the Revystar-treated area – a 0.43t/ha benefit,” he says.

Richard notes that rainfall is always a particular challenge in the South West. “This year was no exception, which affected many autumn drillings for the 2020 harvest. In terms of disease, though, it wasn’t too bad,” he says.

“Rhynchosporium can be a real problem in barley for Cornish growers, and AHDB data shows Revystar is the best product for it. With the loss of CTL, ramularia control is now a particular challenge, and again Revystar is noted as the most effective product, and it also performs among the best on net blotch,” Richard adds.

Just getting the crop in the ground was a problem, though, Mike recalls. “Everyone thought I was mad planting barley in December. The crop established, although the herbicide policy went out of the window and we had to clean up any weeds with sulfonylureas in early spring.

“Then the second calamity hit and we had no rainfall from 20 March until June. It was straw yields this hit the most – the flag leaf barely reached the top of my walking boot. For a farmer in the South West, that’s particularly upsetting,” he comments.

“As Richard notes, we’re in a rhyncho hotspot, so it always pays to use a robust fungicide programme. Two doses of Siltra have generally been considered as good as you can get with CTL added for ramularia, which was the farm standard we used in the trial.

“Generally you couldn’t see much difference between the treatments throughout the season, although the Revystar areas did retain their greenness for longer towards the end, and the disease assessment notes the bottom leaves in particular had less rhyncho.

“But I didn’t expect a yield difference as big as the result we had. So I wonder whether the short crop was more open and leaf four was doing more to contribute to yield. Retaining that GLA became all the more important,” Mike remarks.

Very little ramularia was found in the crop, which concurs with the local and national picture, notes Richard. “The key aspect is to keep the crop stress-free, so it may be surprising so little was found in such a difficult year.”

Mike’s always mindful of ramularia and notes it can be a yield robber. “Going forward we’re being careful not to make too many decisions based on an atypical year. But we’re switching variety to LG Flynn, as Cassia has now become outclassed, and with no CTL, I think Revystar is where we’ll be heading as the fungicide of choice at the T2 timing.”