Following a good result from her in-field fungicide trial, one Cambs grower resolved to get a better understanding of the part played by the soil. CPM checks in to find out.

Keeping the solar panels clean ensures the crop is working efficiently to convert sunlight into biomass.

By Tom Allen-Stevens

Hannah Darby took a slightly different approach with her on-farm trial last year. It wasn’t just the biomass above ground she was looking to build and then monitor closely. She’s also done some exploring beneath the surface to find out what the roots were up to.

With 360ha of combinable crops, based at Sawtry, Cambs, Hannah farms with her uncle, Tony. The farm lies in a basin, at around sea level, but what’s unusual about the soils is that they have organic matter levels of between 30-50%.

Jenni Dungait (left) and Mike Green came to the farm to take some soil core samples at three points in Hannah’s fields last autumn.

“What surprised me was what we found deep beneath the surface,” says Hannah. “I’ve always been very aware of the heavy clay subsoil that lies under the organic silty topsoil and thought it was impossible for any roots to penetrate it. But we found the roots are actually getting down there, or at least they were in the Real Results field, which turned out be the highest yielding field on the farm last year.”

An enthusiast for on-farm trials, Hannah’s referring to a field that was one of 50 in BASF’s Real Results Circle. Now in its fifth year, the growers involved have been carrying out tramline trials with the latest fungicide chemistry, putting the results through a fair degree of scientific scrutiny to ensure a result that’s ‘real’.

Determined to get more from the soils she’s farming, Hannah took up an offer from BASF sustainability manager Mike Green to come to the farm with Soil Health Expert Prof Jenni Dungait to take some soil core samples. This took place at three points in Hannah’s fields last autumn.

“The idea is to find three contrasting points on the farm and assess the physical structure, as well as the carbon the soil contains,” explains Mike. “We take cores in 15cm sections through the profile to around 1m depth and these can be assessed for root content, bulk density and carbon.”

Hannah chose an area at a wooded field edge that hadn’t been disturbed for many decades to provide the baseline – the natural level of carbon the soil will store. The Real Results field was chosen as one that’s in an arable rotation in reasonably good shape, while a field that was in sugar beet followed by spring wheat was known to have a few issues with compaction.

While the full analysis still hasn’t come back from the lab, Mike has a number of observations drawn from what was found on the day. “Unsurprisingly the soil in the best state was in the undisturbed treeline. This just came up like a bag of peat. In the Real Results field there was more body and the soil was at 30% moisture in September. The peaty soil has mixed with the underlying subsoil that we hit at about 85cm. We found roots in that subsoil showing they grow to depth – it’s cultivated land in a good state.”

The field coming out of spring wheat was a different story, however. “We nearly broke the tool trying to get through the compacted layer – it was a very different aggregate, and the soil was dry underneath, showing poor permeability. Crop roots would have found it very difficult to get through that compacted soil.”

Hannah keeps cultivations to a minimum with a 6m Weaving drill cutting the crop into the surface and providing only a light touch in terms of pre-coulter cultivations. “The aim is for only as much disturbance as you need on the surface to help keep the carbon cycle going and generate biological activity,” she says.

Mike believes that’s the secret to sequestering carbon and ensuring a healthy soil. “It’s important to keep that activity going – the roots and straw will add to the carbon that’s left once the crop has gone and the more biomass you generate as the crop is growing, the more carbon, as well as natural structure, you build into the soil. That means it’s also important to have a healthy green leaf area above ground to capture as much of the available sunlight as possible.”

That’s where Real Results comes in. Mike points out that fungicides have a very low carbon footprint compared to the biomass they can add to the crop through improved yield. “Keeping the solar panels clean ensures the crop is working efficiently to convert sunlight into biomass.”

Hannah’s joined by agronomist Rob Wilkinson of Strutt and Parker and BASF’s Andrew Smooker in a Zoom call to discuss the season and the results of the trial in particular.

“The high carbon soils can pose a challenge at establishment,” notes Rob. “The crop roots need encouragement to go exploring for nutrients, and residual herbicides are easily bound up. But the benefits are workability and plenty of available N. This is land that likes to be farmed.”

Hannah reports the Real Results field recorded available N of 253 kgN/ha when sampled last Feb, which formed the basis for nutrition through the season. The variety chosen was LG Skyscraper, grown on contract for seed, drilled following peas.

“Skyscraper’s one of the better varieties,” notes Rob. “It grows a little tall but it’s robust with a good disease package, there’s not much there to worry about.”

Although early sown, relative to other crops on the farm, it was fairly free of disease as the T0 timing approached, recalls Rob. “But some yellow rust crept in, so we added some tebuconazole to the CTL.

“Despite the hot and dry March, April and May, the crop was clearly showing potential in its plant stand and tillers, and that informed a fairly robust T1 application of Pexan with CTL. One disease we didn’t see was mildew – a common problem on these high organic soils – which meant we could leave out the Talius (proquinazid).”

Hannah and Rob have been careful to keep the crop’s nutrition in balance to improve overall plant health and resilience against disease. “We’ve been keeping a close eye on manganese, that can go short on these soils, making applications of foliar Mn through the season so the crop doesn’t come under stress,” he adds.

“We were about to shut the gate on the field when brown rust came in late in the season, so a late dose of tebuconazole was applied.”

Hannah’s pleased with the results from the field, both in terms of the crop it yielded and the state of the soil. “Of course we want to maximise profitability, but we also want to be sure the way we’re farming is sustainable, especially on these high carbon soils and with so much pressure to restore peatlands. With the right management we can cultivate a high yielding crop and feed the carbon cycle,” she concludes.

The right rate keeps crop at full potential

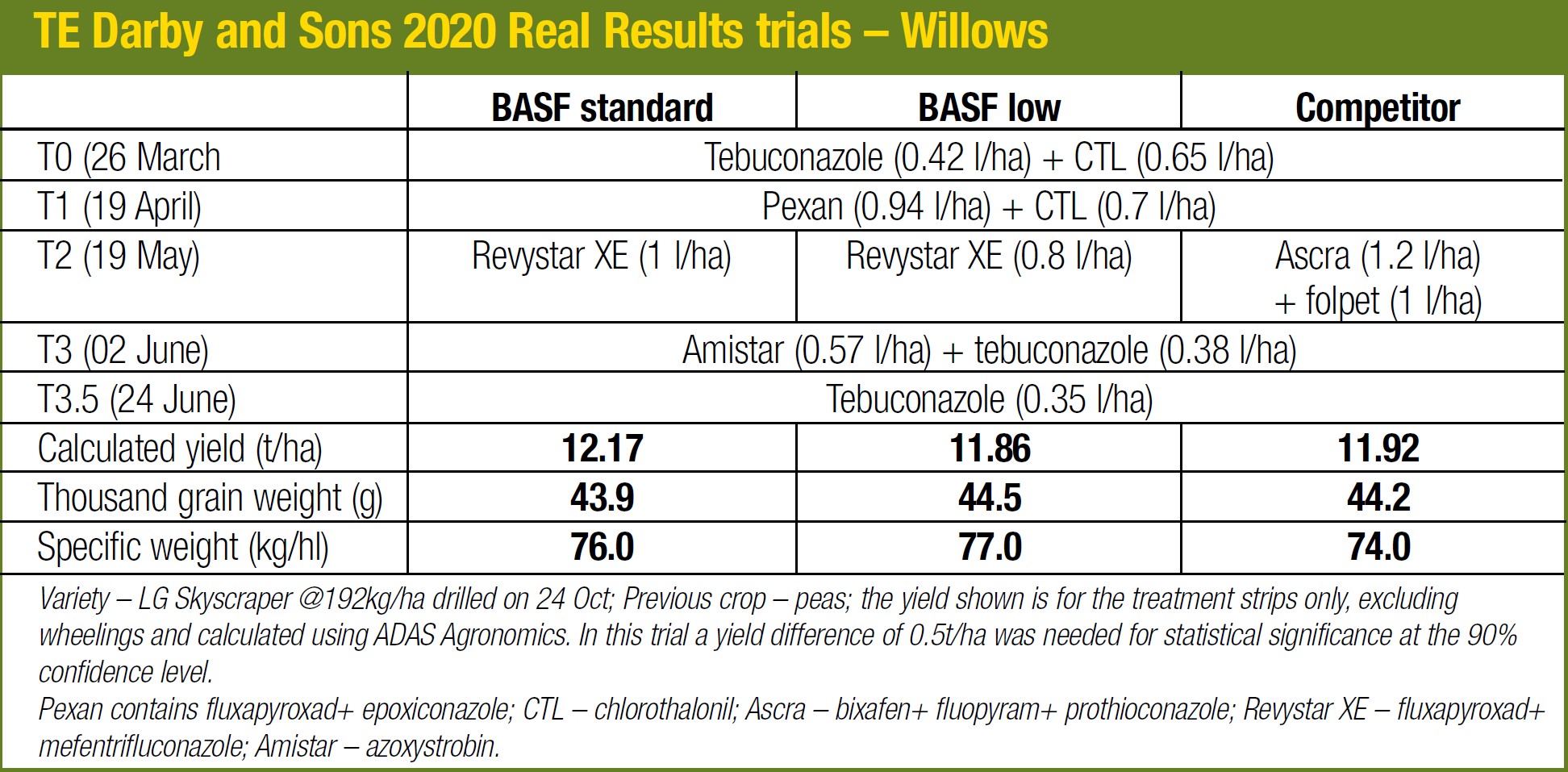

Historically the BASF fungicide treatment is pitched against the farm standard in the Real Results trials. In Hannah’s field last year, two different rates were also compared, explains BASF’s Andrew Smooker.

“It was the first commercial year for Revystar XE, and we’re keen to pull apart the differences you get from adjusting rates, especially in a high performing crop like this one.”

No CTL was applied across the programme to compare fungicide options available in 2021 and beyond, while the trial’s also been a chance to compare options for keeping rust in check. “Revystar has a particular strength on septoria. But with epoxiconazole losing its approval for use this year, that’ll put an emphasis on early control of yellow rust and then maintaining this through the season.”

The standard rate of Revystar at T2 is 1 l/ha, he explains. “We get a lot of enquiries about dropping rates, especially given some recent dry springs. There may be occasions when this is tempting but it’s important to consider the overall risk – in most situations and seasons there’ll be a period of weather that will tease out the difference. Likewise, maximising the potential of a crop is the aim of using Revystar, as reflected in Hannah’s results.”

A Powerzone map, created in the xarvio digital platform, brings in data over 15 years to show areas of greatest potential, which tallies with Hannah’s experience. “There’s notably lighter soil towards the east of the field, while in the middle there’s a silty ridge and nice high yielding area,” she says.

While all parts of the trial area received the same T1 spray, the comparison treatment at the T2 timing was 1.2 l/ha Ascra, which Rob reckons is the best alternative treatment available. “In the end you couldn’t really pick out any differences in how the different treatments came through the season – it shows the importance of a proper scientific analysis,” he notes.

In a year with very low septoria levels, rust appeared in susceptible varieties across the region, although well timed spray programmes kept the disease in check, he reports. Disease was assessed in the Real Results crop in mid June and then again in mid July, with septoria the only disease observed in the first assessment, at low levels on all leaf layers.

On the flag leaf, septoria was significantly lower in the BASF treatments than the competitor. At the second assessment, septoria severity on leaf two was significantly higher in the BASF low rate than the other two treatments. Yellow rust was also present at low levels, but with no differences in severity between treatments.

Calibrated yield data taken from the combine was analysed using ADAS’ Agronomics tool, which delivers statistical confidence to tramline or field-wide treatment comparisons. The effect of this was to show a yield increase of 0.25t/ha for the Revystar standard rate over the competitor programme with a small yield penalty where the Revystar rate was reduced. The differences were not statistically different, however, and could have been caused by soil variation, for example.

With fewer tools to tackle disease this year, Andrew recommends a holistic approach to both yellow rust and septoria, keeping both in check from the start of the season, with Revystar used at the standard rate. “In a low disease year, you get the benefit from green leaf area retention, while higher rates can be considered if conditions are wetter.

“Comet (pyraclostrobin) can be added for enhanced protection if rust is likely to become a problem,” he adds.

The results of the trial are “food for thought”, says Hannah’s. “It’s reassuring to know that, despite the loss of CTL and epoxiconazole, we’ll be able to keep the crop at full potential, and useful to get a further insight on Revystar.”

The Real Results Circle

BASF’s Real Results Circle farmer-led trials are now in their fifth year. The initiative is focused on working with 50 farmers to conduct field-scale trials on their own farms using their own kit and management systems. The trials are all assessed using ADAS’ Agronomics tool which delivers statistical confidence to tramline, or field-wide treatment comparisons – an important part of Real Results.

In this series we follow the journey, thinking and results from farmers involved in the programme. The features also look at some in-depth related topics, such as fungicide performance and data capture and use.

We want farmers to share their knowledge and conduct on-farm trials. By coming together to face challenges as one, we can find out what really works and shape the future of UK agriculture.

To keep in touch with the progress of these growers and the trials, go to www.basfrealresults.co.uk