From the AD unit to the soils, every operation for one Oxon grower revolves around ensuring there’s a thriving community of micro-organisms working hard to produce goodness in a low carbon system. CPM explores.

By Tom Allen-Stevens

At the back of the spray shed there are three IBCs. In one there’s a heater element, the next has an agitator while the third contains fermented molasses, fulvic and humic acid.

The series of IBCs are used to brew microbes from a concentrate that are then added to the spray tank.

“We’re dosing the soil,” explains James Taylor. “What’s clear to me is that every time we make a pass with the sprayer, we deplete the soil biology. So we brew up replacement microbes from a concentrate that are added to the spray tank. This batch will go in the glyphosate I’ll be applying to the cover crops.”

It’s not just in the fields where there’s a focus on biological activity. Across the yard from the spray shed is Taylor Farms’ 500kW anaerobic digester. Brought into service in October 2014, it’s fed a diet of maize and rye silage as well as chicken manure, with fresh grass brought straight in from the fields during the spring and summer months. “Some people ensile their grass, but my digester likes it lush and green and full of sugar,” he notes.

The care and attention he’s brought to the microbes in the AD unit, ensuring they have a balanced diet for peak performance, he’s now bringing to his soils. The cropping, cultivation and inputs across the 290ha family-owned farm near Banbury, Oxon, are all geared towards the regenerative agriculture system he follows.

“There’s a carrot-and-stick approach that’s driving change for farming under current government policy. For me, the carrot is sustainability,” James explains. “I think AD units get a bad reputation from a small but vocal minority who are critical of the contribution they make to reducing carbon emissions. But the rotation we have, the way we’re cycling nutrients and improving the soils all show there’s a lot of misconception about what you can achieve.”

The gas produced by the microbes fuels a generator producing enough green electricity for around 900 homes. Waste heat from the plant dries woodchip from timber imported, chopped and sold on. “We’re currently getting all of our timber from within a 50-mile radius,” notes James.

“One of the key aspects I’ve learnt from the microbes in the digester is that they have a carbon:nitrogen (C:N) balance they like and that they want maintained. That applies across most of nature, so it’s a balance we want to get right in the fields, too. We’ve used rotation, biology and better use of digestate to reduce our use of inorganic fertiliser by 30%. If we can get our biological house in order, the aim is to feed almost all crops through digestate alone.”

Helping him on this quest is Ben Harrington of sustainable agriculture specialists Edaphos. “Soils contain a whole host of micro-organisms, both beneficial and pathogenic, that can be synergistic and carry out many key activities. A healthy soil has a balance, and if this is upset, that’s when the pathogens can start to cause problems,” he explains.

“One of the useful functions micro-organisms can perform is their role in the break down of chemical residues, and pesticides such as glyphosate will break down well in a healthy soil. Where a soil’s deteriorated though, there’s limited microbial activity, and that’s where you begin to see problems with chemical build up, as well as potential soil erosion and leaching leading to further impacts on the environment.”

A soil inoculant can help reset the balance in a degraded soil, he says, alongside creating more optimal environments for biology. “It has best effect when used as part of a strategy to build soil biology, including a wide and diverse rotation with minimum cultivations. And maintaining an adequate C:N balance is crucial for healthy soils to ensure both habitat and food source for microbes, alongside encouraging many other benefits a healthy and microbially active soil brings.

“High levels of excess nitrogen can lead to further burn-off of stabilised organic matter within the soil to account for the necessary C:N ratios of micro-organisms and their activity,” he adds.

A Sly Stripcat is used to pull cultivated strips, or berms, through the cover crop into which the maize is planted a month to six weeks later.

The farm’s rotation pivots around maize. This alternates with winter or spring rye while there’s 22ha of two-year grass ley and currently 19ha of spring barley. But the rye crops are not really just rye. “We’re moving away from mono-cropping so there’s a fair mixture grown with the KWS Edmondo hybrid rye including winter barley and oats. Most crops have some sort of legume inclusion to help build soil biology, so the mix includes vetch while we’ve undersown with white clover,” explains James.

“The main advantage of hybrid rye is that it has a low N and fungicide requirement, which helps us maintain the soil biology balance. There’s also been good progression in the varieties with shorter straw and bigger ears.”

John Burgess of KWS points out that KWS Serafino is new on the AHDB Descriptive List – a step-up in yield at 111% of controls – while KWS Tayo looks equally promising as a candidate variety. “Both are stiff with leading scores for brown rust, and both are dual purpose grain hybrids – the starch content benefits the digester.”

James is considering growing both varieties in the autumn in his winter rye mix. Meanwhile this spring he’s going to try mixing in peas as a companion crop to the spring rye. “We did a trial with sainfoin which didn’t really take last year. We’re drilling at the end of March to early April with no pre-emergence herbicide, so we’re looking for good rapid ground cover.”

He’s planning to sow KWS Arantes, a variety that John says “grows with exceptional speed”, going from planting to maturity within three months.

The cereal crops are fed as much as possible with digestate, which includes a dose incorporated early in the autumn to get the cover or catch crop going. “We’re trying as far as we can to build the available N in the soil so we can eventually eliminate inorganic N inputs. The difficulty is getting the organic N released at the point the crops needs it,” says James.

A strategy he’s trying, for example, is to spray off the cover crop, which includes oats, vetch and winter beans, with a reduced dose of glyphosate that leaves the bean crop standing for longer.

“While we top dress the cereals with digestate, it’s difficult to get enough organic N into maize and make it available to the crop with reduced cultivations.”

James grows early or ultra early maize varieties such as KWS Augustus, Artikus and Exelon. “We know we’re losing a little bit in yield by growing a variety that comes to harvest early, but it means you can get the cover crop in earlier and harvest in better conditions.”

Another big step he’s taken to ensure the crop is more sustainable is through the cultivations he applies. He uses a Sly Stripcat to pull cultivated strips through the cover crop around a month to six weeks before drilling maize. “Not all the soil’s moved, and this leaves much of the biology undisturbed that can quickly recolonise the part of the soil that has been cultivated. We then drill with a five-row Horizon Precision Planter on around 20 April using RTK guidance into the berm, or raised strip.”

On the cereals side, a 6m Horsch Avatar has just taken over from the farm’s Horsch Sprinter with all crops now direct drilled. “We looked at three drills last autumn – the Cross Slot, John Deere 750A and the Avatar. The advantage with the Avatar was the flexibility – every other row can be a different crop type,” he notes.

And there’s little doubt the system’s working across James’ soils which vary from sandy/clay loam to limestone brash. He takes a spade and digs up a clod – this brings up a mass of roots clustered with nodules and worms can be seen shrinking away from exposure.

But these soils are not producing food. “We do grow spring barley for my brother’s beef herd just next door, and I’d like to have a local market to supply, such as rye for a local distillery. But it doesn’t sit right with me that a farm should produces grain that’s taken many hundreds or thousands of miles away to be processed. We are, however, growing our own micro-greens.”

the micro-greens are grown using electric and waste heat from the plant and sold through nearby Daylesford Organic Farmshop.

James wanders over to a shipping container close to the AD plant. He opens the door, and as you step in, you’re enveloped in a warm, moist atmosphere. Inside are trays of seedlings on shelves under LED lights. “We grow peas, sunflower, radish, rocket, mustard and herbs. The compost is sustainably sourced, although we intend to make our own, and packaging is biodegradable. It’s all fed from the electric and waste heat from the plant with a crop turnaround of as little as ten days,” he explains.

“We sell the micro-greens to a premium market through nearby Daylesford Organic Farmshop and that brings us closer to the customer. We’re lucky to have the digester that gives us the opportunity to try a venture like this, which meets squarely with our sustainable objectives. But the other important aspect is that it’s a closed system in which we remain in control of the end use of our crops and have the freedom to develop the environment in which they grow.”

What makes James Taylor a Climate Change Champion?

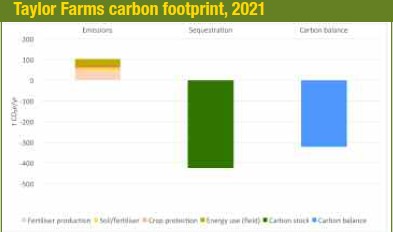

Source: Taylor Farms, March 2021, calculated using Cool Farm Tool. Figures shown are indicative and exclude fossil fuels displaced by energy produced by the AD unit.

Innovative ideas

James has taken what’s he’s learnt from how microbes perform best in the anaerobic digester and applied this to his soils. The biology lies at the heart of a soil-health improvement programme that goes beyond securing a sustainable future for the farm business – it addresses the misconceptions around energy generation from AD.

Productivity push

Mono-cropping has been abandoned in favour of a blend of crop types and varieties that support each other, bringing maximum productivity for minimum resource outlay. There’s on-going success in driving down inorganic N applications, switching to more sustainable sources.

Cultivation care

It’s a challenge to reduce cultivations sustainably in maize, but James has achieved this through the strip-till system he’s adopted. With this and the direct-drilled cereals, again the focus is on the right environment for the soil biology to thrive.

Bio-based boldness

Freed from commodity production, James adds value to the crops he produces through the digester, deriving income from the electric and heat it produces, as well as supporting a new micro-greens enterprise. In addition, he’s displacing massive amounts of fossil fuel.

A peak carbon balance achieved with the right crop types

Peak performance from an anaerobic digester requires crops that deliver the optimum balance of feedstock for resource expenditure. But it’s not just about yield, notes John Burgess of KWS.

“Hybrid rye is a crop that needs as little as 45% of the N of winter wheat, depending on type, and just 33% of the fungicide use according to a recent analysis carried out by Velcourt’s regional agronomist Kieran Walsh. There’s less leaf area to protect compared with wheat – rye utilises the stem and ear more for yield formation. This gives the crop a very favourable carbon balance,” he says.

“It means hybrid rye’s a good crop for a digester and it’s grown extensively across Germany, where there are the most AD units of any country across Europe. We’ve brought that experience into varieties best suited to the UK climate,” he says.

When it comes to maize, John notes that the UK crop is currently at a record high of 230,000ha. “One of the reasons is an earlier harvest and this is down to improved reliability of early varieties. This has a yield penalty, but the flipside is less risk. They also need less N, which improves the carbon footprint. Growers in Germany have had success inter-row planting their maize with runner beans, which improves the sustainability of the crop further.

“The beauty of James’ system is that he’s not caught by commodity production. This gives him the flexibility to develop an approach to growing, perfectly matched to his soils. What he’s done is apply innovative thinking to get the peak performance he’s looking for, which makes him a worthy Climate Change Champion.”

Climate Change Champions

UK Farming has set itself the challenging target of Net Zero emissions by 2040. Although led by the NFU, it will take the entire industry, working together in a partnership approach to meet this ambitious goal.

But there are individual growers, thought leaders who have already started on this journey. They have the ideas, the progressive outlook and the determination to shape positive change. CPM has teamed up with leading agricultural suppliers who have a credible Net Zero aspiration to identify these individuals and bring them into the top-level discussion about how farming can position itself as the solution to climate change.

CPM would like to thank our sponsors:

Agrii, BASF, BKT, CF Fertilisers, KWS, Interagro, Lloyds Bank, Small Robot Company