On a North Norfolk estate, where roots are the main cropping priorities across drought-prone soils, how does the fungicide policy on the wheats fit in? CPM finds out.

We’re doing everything we can to build the shoots and the leaves above ground that put the roots down below.

By Tom Allen-Stevens

Set in 950ha of North Norfolk near Swaffham, the aim at The Wicken is to blend the estate’s rural assets so they work in harmony – both for a thriving environment and for its cropping enterprises.

“My job is to ensure there are sustainable farming activities that provide the thriving biodiversity the estate needs,” says farm manager Toby Hogsbjerg.

Along with increasing the soil organic matter, the cover crops mobilise phosphate and improve the soil structure at depth.

Everything meshes in together, he notes, with the biodiversity generated from around 100ha in Countryside Stewardship or other environmental management also benefiting the root crops. And it’s these that form the main cropping enterprises on soil types that vary from blowing sand to sandy clay loam. 110ha of sugar beet, 80ha of potatoes and a further 80ha of land let out for onions and parsnips. 220ha of winter wheat, 170ha of winter and spring barley and 80ha of spring peas currently complete the cropping picture.

Toby’s always taken a measured and managed approach to changes he makes to cropping, informed through on-farm trials. “You have to test the changes you make on your own farm and your own soils. That’s especially important when you’re not familiar with the history.”

He took up the job at The Wicken in October 2018, and was previously farm manager at Swinbrook in the Cotswolds, where CPM last caught up with him in Sept 2017. While much has changed, testing and monitoring through on-farm trials is a key discipline Toby’s brought with him.

From the start, he’s also been one of the 50 BASF Real Results farmers carrying out tramline trials with the latest fungicide chemistry and putting the results through a fair degree of scientific scrutiny to ensure a result that’s ‘real’ (see panel on pxx).

So what else has Toby brought with him from the Cotswolds? “Managing drought-prone soils is a key aspect of farming at The Wicken. The soil type is very different – at Swinbrook they are shallow over brash, while here they are light. But in both cases, using cover crops and grazing with sheep really helps.

“The cropping itself, however, is totally different. The rotation revolves around what we can comfortably irrigate, which is available across 95% of the estate. Sometimes we also irrigate spring barley and peas. The challenge we have is soil with an organic matter below 2%. We won’t turn that round overnight, but we’re doing everything we can to build the shoots and the leaves above ground that put the roots down below.”

Cover crops form the main route to building soil organic matter. A mix of vetch, rye, turnips, forage rape, radish and crimson clover is grazed from October to February under an arrangement with a neighbouring shepherd. In front of potatoes there’s linseed, buckwheat, phacelia, brown mustard, radish, vetch and clover.

“Along with increasing the soil organic matter, the cover crops are doing two other important jobs in front of the potatoes: mobilising phosphate and improving the soil structure at depth. So we’re looking increasingly at how we can choose species and encourage rooting at depth.”

Toby’s already noticing the difference on the surface with soil that doesn’t cap as much as previously. He’s gradually cutting cultivations, with the main tillage tool being a 4.4m Horsch Terrano, fitted with a Duodrill to establish the cover crops. This is pulled through shortly after harvest with legs set at a depth of 150-200mm, and the seed distributed in front of the packer roller.

The cover remains in place until Jan or Feb when land preparation gets underway for the root crops. Cereal crop establishment poses more of a challenge, however, especially during the past two seasons. “We received 562mm of rain between Sept 2020 and Jan 2021. The biggest issue we have is getting the crop established after roots and then getting it away in spring before the land dries out.”

This puts a very different perspective on disease control from what Toby managed in the Cotswolds. “You don’t get the septoria pressure, although there’s more of a job keeping yellow rust out early in the season. We had a problem with mildew last year following the wet winter and delayed drilling.

“After that, you need a crop you can manage flexibly, treating what you see in front of you. Our focus later in the spring is on blight control in potatoes – we simply don’t have the capacity to firefight a fungal issue in the wheats.”

Varietal resistance is increasingly the tool of choice here, with Theodore coming in as a mainstay wheat for its strong disease scores. Grown as a seed crop, alongside SY Insitor and KWS Kerrin, Skyscraper and KWS Kinetic have been dropped from the wheat portfolio.

“Chlorothalonil used to be the staple choice to start off the fungicide programme. Now we largely rely on genetics to keep the crop clean. I’m hoping Theodore, with its high score for yellow rust as well as for septoria, will help. It’s certainly clean at the moment, although crops are only just getting going after a cold spring,” reports Toby.

This change of emphasis in the early season fungicide programme means that only where yellow rust is spotted will a wheat crop get a T0 fungicide, and he recognises this puts more emphasis on the T1 application. “Last year we used Adexar (epoxiconazole+ fluxapyroxad) at T1 followed by Reystar XE across much of the wheat crop. This year we have some left-over Adexar that we’ll use at T1, although that won’t be an option going forward. Elatus Era (benzovindiflupyr+ prothioconazole) is the other farm standard application we used last year due to rust pressure.”

While the choice of T1 chemistry is still undecided this year, looking ahead, he’s also planning to make more use of disease support systems to inform his fungicide applications. Toby’s using a weather station and for the second year is also running a trial with xarvio Field Manager. This is a disease support platform that uses local weather data and cropping information to deliver recommendations, based on calculated risk of disease prevalence.

“Last year, we did a variable rate application trial on our barley using management zones set up within xarvio,” he explains. “This varied the rate of Siltra (bixafen+ prothioconazole) and Canopy (mepiquat chloride+ prohexadione-calcium) at T1, and then Siltra and Terpal (ethephon+ mepiquat chloride) at T2. The principle worked well and picked out the differences across our variable crops. But unfortunately, the field was combined wrong, so we don’t have the results to verify what we saw.

“We’re planning to repeat the trial this season, but we’re also learning more about how Field Manager can help us reduce fungicide applications and tailor them more reliably to risk. It’s good to get an insight on how the models it works on help you decide whether you stick or twist as the season progresses.”

Toby sees these tools as part of the fabric of crop management that allows him to focus on the priorities of the estate at The Wicken. “Root crops will always remain the main cropping priority, while the farming has to complement the farm’s environmental assets. That means key aspects for cereal crops are getting them established well and looking after the soils. So you treat what’s in front of you and use the best of the technology and tools available to deliver the best results,” he concludes.

A Real Result for green leaf area produces a comfortable margin

The sandy loam of Five Hills, the field where the Real Results trial took place last year, was never really going to deliver a yield-topping performance, no matter what chemistry was used, and weather challenges last year also conspired against it. But the results have been nonetheless a considerable eye-opener for Toby.

“Success on these soils is all down to establishment, which can be a challenge after roots in any season. Here the crop followed oilseed rape, but established in late October, like most of the wheats, we used a plough/power harrow combination and didn’t protect the crop from the heat and drought that followed in the spring and summer – the trial just turned to dust.”

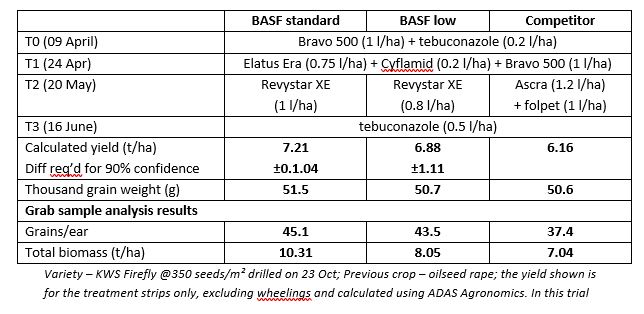

KWS Firefly, the variety used, fared comparatively well in the challenging autumn conditions, he notes. The level of disease was assessed on 12 June at GS65 by ADAS and again on 10 July. Extremely low levels were found, although there was a consistent trend for highest percentage green leaf area (GLA) in the areas treated with Revystar XE at the standard rate.

“The soil type in that part of the field is very variable, and as you walked through it you could pick out the differences in GLA between treatments with the naked eye,” confirms Toby. “There wasn’t much disease for the Revystar to tackle, but clearly it delivered in terms of physiological effects.”

He’s joined by local BASF agronomy manager Hugo Pryce to assess results. “When we flew over the field with the drone, that also helped us pick out the differences between treatments. We know that Xemium does increase water use efficiency and the combination with Revysol has helped during that dry time,” he says.

Grab samples were collected from the trial on 24 July, shortly before harvest. 15 whole crop samples of 50 tillers each were taken from each treatment and separated into straw, grain and chaff components to assess differences. The underlying variation in the field means there were no significant differences between treatments, according to ADAS. However, the grab samples suggest a much higher total biomass achieved in the area treated with Revystar, relative to the Ascra treatment.

“This complements our wider dataset demonstrating an improvement in HAD (Healthy Area Duration) in both high and low disease scenarios, and across multiple strengths of variety,” continues Hugo. “With an increased market focus on retaining green leaf across the whole canopy, Revystar provides a proven opportunity to build yield.”

The trial results appear to confirm this. The average measured yield of the farm standard treatment was 6.16t/ha, according to yield map data. The modelled effect of the standard rate Revystar treatment was to increase yield by 1.05t/ha, relative to the Ascra treatment, which was a significant difference at the 90% confidence level, according to ADAS. This result was achieved despite the low level of precision in the trial, due to the strong underlying variation in yield, which ranged from 4-11t/ha.

“Delivering a yield benefit of over 1t/ha in a very low disease year demonstrates Revystar brings a significant margin over fungicide cost purely from its physiological benefits – it’s not just a great product on septoria,” notes Hugo.

It’s been a reassurance for Toby, too. “We always aim to go with appropriate treatments and spray for what we see in front of us. On land that droughts out, you have to know if you’re going to get your money back when you spend on premium fungicides. The trial shows Revystar achieved that, despite very challenging conditions last year.”

The Wicken 2020 Real Results trials – Five Hills

The Real Results Circle

BASF’s Real Results Circle farmer-led trials are now in their fifth year. The initiative is focused on working with 50 farmers to conduct field-scale trials on their own farms using their own kit and management systems. The trials are all assessed using ADAS’ Agronomics tool which delivers statistical confidence to tramline, or field-wide treatment comparisons – an important part of Real Results.

In this series we follow the journey, thinking and results from farmers involved in the programme. The features also look at some in-depth related topics, such as SDHI performance and data capture and use.

We want farmers to share their knowledge and conduct on-farm trials. By coming together to face challenges as one, we can find out what really works and shape the future of UK agriculture.

To keep in touch with the progress of these growers and the trials, go to www.basfrealresults.co.uk or scan the QR code to visit the all-new, cereal fungicide virtual trial, offering a 360° map to compare plots.