Tyres can make all the difference to performance and fuel use, as well as to soil compaction and erosion – which is why manufacturers are constantly looking to bring improvements to these fundamental tools. CPM looks at some of the latest launches.

Our latest tyres are ready for an entirely new generation of machines, in size and specifications.

By Melanie Jenkins

It doesn’t matter what machine or piece of equipment is being run on farm, the chances are it needs tyres. But having the right tyre for the job – be is spraying, combining or hauling – can make a big difference to running costs, efficiencies and protecting soils. Here are some of the latest launches from manufacturers aimed to improve farm operations.

BKT

The FL 695 in an agro-industrial tyre specifically designed for trailers in farming.

BKT launched a new tyre for agricultural trailers in June. The FL 695 in an agro-industrial tyre specifically designed for trailers in farming and construction transport applications. BKT claims that this radial tyre is resistant and durable thanks to a strong casing with multiple steel layers providing protection against punctures.

The tread has been designed with a centre-block pattern that should provide stability and resistance in all conditions and with heavy loads. The tyre is currently available in size 650/55R26.5.

Claas

From summer 2022, Claas is integrating Terranimo into its CEMOS functionality for tractors. CEMOS already assists operators with machine settings by accommodating soil humidity, soil type, working depth, implement data and tyre model, but with the introduction of Terranimo it has added another level of sophistication. Based on the combination of the aforementioned parameters, the computer model predicts the risk of soil compaction from agricultural machinery on three different levels of the soil profile. From this, users can adjust ballast and tyre pressure to further protect the soil.

Terranimo predicts the risk of soil compaction from agricultural machinery.

The firm has also recently introduced new track widths for its Axion Terra Trac. In addition to the current 635mm and 735mm wide rubber belts, two new variants are now available to provide both narrower and wider widths. The 457mm narrow tracks are for use in row crops, for example spreading organic fertiliser or working with hoes.

The 457mm narrow tracks, as well as the 635mm and 735mm wide standard tracks can now also be supplied with a 3m tread setting in selected markets. This makes it possible to work in controlled traffic farming applications and to further improve manoeuvrability.

Since autumn 2021, the Axion Terra Trac has also been available with 890mm wide tracks, but the overall width still remains below 3m. These belts are aimed at reducing soil damage and compaction on fields and grassland. According to the firm, the active belt control when steering means there shouldn’t be any surface damage when turning tight.

The Axion Terra Trac can also now be equipped with the Claas CTIC tyre inflation system on the front axle. The front tyres are filled using the air compressor for the air brake system.

Compaction Prevention System

A Swedish team of farmers, advisors, researchers and civil engineering students has taken further steps to help prevent soil compaction with the invention of a concept called Compaction Prevention System (CPS).

CPS should be able to help farmers forward plan as well as making real-time decisions while in the cab.

So how does it work? Initially a computer processor is fed with information about soil pressure, soil type, soil moisture and field status. The latter is included because roots from growing crops can make the soil less susceptible to pack damage, says Alice Molin, a civil engineering student and part of the team behind the invention.

The information is updated in real time and communicated through a risk meter that the farmer can have in the cab and by using maps, which can also be analysed at the farm office, says Axel Lagerfelt, technology agronomist, farmer and part of the team.

CPS should be able to help farmers forward plan as well as making real-time decisions while in the cab, believes the company. This could be through information about the risk of soil compaction for different parts of the field or by keeping an eye on compaction while in the field with the packing risk meter, which provides continuous information to the operator.

Continental

Continental’s ContiPressureCheck monitors the

pressure and temperature of tyres using sensors in the tyre.

Continental has introduced a new intelligent aspect to its combine tyres. CombineMaster and CombineMaster VF tyres can now be specified with ContiPressureCheck, a tyre monitoring system that aims to help prevent downtime during harvest.

ContiPressureCheck monitors the pressure and temperature of tyres using sensors in the tyre. This communicates the pressure and the heat build-up to help the operator decide on the optimum operating pressure. There are two warning levels offered by the sensor. The first suggests that a fault has occurred, but the machine can continue to work. The second calls for an immediate stop due to a more severe tyre problem.

“This is a good way to improve the life of combine tyres and reduce unnecessary downtime. Operators can choose to have a handheld device, or a terminal mounted in the cab,” explains Rebecca Sheddon of Continental. “Both will feed back information on the tyre and help the operator to make adjustments that will reduce the likelihood of tyre failure.”

ContiPressureCheck also provides tyre data without the need to touch the valve – the most sensitive part of the tyre. It therefore aims to offer a safer and more secure way to monitor tyres and reduces the likelihood of dirt affecting the valve, adds Rebecca.

Mitas

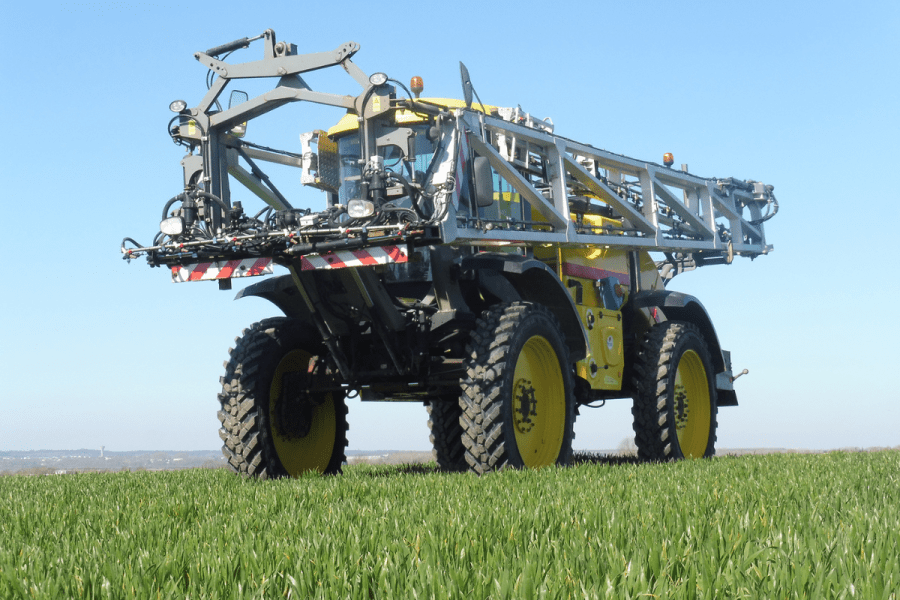

Mitas’ new radial tyres are designed to give a secure fit even at low pressures

Mitas has introduced two new High Capacity (HC) radial tyres designed for the next generation of self-propelled agricultural sprayers. The HC 1000 tyre line includes two new Narrow Rim Option (NRO) sizes, the VF 650/65R38 and VF 750/60R46, made to handle high load capacities and operating speeds.

“Our latest tyres are ready for an entirely new generation of machines, in size and specifications,” states Pavel Kott of Mitas.

According to the firm, the VF construction aims to deliver several benefits – carrying up to 40% higher load capacity with better traction, ground protection and crop yields. Pavel says the NRO construction should also help with cost saving as the new VF tyres are built for mounting on standard rims.

The new Mitas tyres are designed to give a secure fit even at low pressures, as well as a longer lifespan, says Pavel.

Michelin

Michelin has launched a new version of its Evobib tyre. The Evobib is the first agricultural tyre on the market specifically designed to be used with Central Tyre Inflation Systems (CTIS). This should allow it to obtain good performance on the road and in the field due to its adaptive design, says the firm.

In field use, the footprint is maximised due to the tread design, and its very low-pressure structure (Michelin Ultraflex Technologies) is designed to reduce soil compaction and improve the tractor’s traction capabilities.

In road use, the reduced footprint and the central rib of the tread pattern is designed to lessen rolling resistance. In addition, longevity should be improved, and fuel consumption reduced, claims the firm.

The tread design has been adapted to optimise longevity and offer good traction capabilities until the end of the tyre’s life. In this new version, the tyre casing is now Pressure Field Operation (PFO), a standard that allows tyre manufacturers to increase the load capacity of their tyres for field use.

A footprint variation of 47% between road and field, is around double that of a VF tyre – like the Michelin Axiobib 2 (24%) – that would have usually been used with CTIS.

The Evobib has around a 15% increase in traction compared to a competitor’s VF tyre with a hybrid tread pattern, and the same traction capability as a VF tyre with a lug tread pattern (under normal field conditions), according to the firm.

Fuel consumption should also be close to that obtained using a standard road profile tyre. The Evobib has demonstrated a reduction of one litre per hour compared with the Axiobib 2 with CTIS.

Two sizes of the Evobib are available, the VF 710/70 R 42 and VF 600/70 R 30. These can be fitted to tractors between 200-300hp, equipped with CTIS. The range will expand in 2023 with the addition of new sizes for tractors of >300hp.

Michelin recommends that if more than 80% of usage is in fields and/or difficult working conditions, the Axiobib 2 is preferred because of the traction capabilities offered by its lugs.

For between 20-80% field use, the Evobib with CTIS helps to optimise performance characteristics on the road and in the field, says the company.

If the field usage is less than 20% (mostly road use), and the tractor is not required to work in extreme conditions, Michelin advises using tyres like the Roadbib, as these will be the most suitable option due to its increased longevity and better fuel efficiency.

Alliance

The Alliance The 372 VF has had a construction upgrade and a new, modern stubble guard compound.

Alliance has extended its range of agricultural tyres with the introduction of the 372 VF – its flagship tyre in VF technology. There’s also a new size of the Alliance 363 VF row crop – its tyre for on-road drive and low wear, and a new size of the Alliance 585 – designed as a versatile tyre for telehandlers, backhoe and compact loaders.

The 372 VF has had a construction upgrade and a new, modern stubble guard compound. The tyre now comes in the additional size VF 710/60R34 and is designed to provide fuel efficiency, powerful traction, low slip and large footprint to deliver effective soil protection.

The 363 VF features a hybrid design specifically developed for tractors and sprayers with an extensive usage on the road. This high-speed steel-belted tyre with VF is now also available in size 380/105R50 and 480/80R50. Its key feature is claimed to be low wear and long tyre life. According to the firm, this tyre is able to last twice as long on roads when compared with standard tread designs – and should still deliver traction and self-cleaning characteristics in the field as well as a comfortable ride, low vibration and low noise on the road.

The 585 is a versatile agro-industrial steel-belted tyre which can be used on hard surfaces, loose gravel and soil. This tyre is now also available in size 305/70R16.5 and 265/70R16.5

Ascenso

LAMMA 2022 marked Bush becoming the exclusive distributors of Ascenso tyres in the UK. Ascenso offers a large range of agricultural tyres including the IMB 160 and IMB 161 implement tyres. Both have been designed to minimise soil compact and protect grassland. These tyres are made from a nylon carcass to provide high load-carry capacity.

Apollo

The new Vredestein Traxion 70 features curved lugs and a large contact area in the middle of the tread.

Apollo Tyres has completely renewed its Vredestein Traxion 70-series tractor tyre. Fifteen sizes are available, offering a range from 41-107cm. All 25 tyres are available for the aftermarket and various tractor brands are offering them factory fitted. Traxion 70 is Vredestein’s follow-up and redesign of the popular Traxion+.

The new Traxion 70 features curved lugs and the large contact area in the middle of the tread. Together with its unique compound, this should result in a longer lifespan than that of its premium competitors, says the firm.

GRI

GRI has launched its most environmentally friendly tyre yet, the Ultimate Green XT. “Environmentally sustainable growth is our strategy today and for generations to come,” explains Mahesha Ranasoma, CEO of GRI. “We are working towards this goal through the way we produce our tyres as well as developing new tyres. The Ultimate Green XT solid tyre for the material handling industry is a result of our drive to create and manufacture products that are sustainable.”

The tyre contains 42.8% sustainable materials, which includes bio-sourced and recycled materials. The tyre is built with pure natural rubber, silica, recycled carbon black and reclaimed rubber from used tyres. The tread compound of the tyre contains highly dispersible silica and no carbon black, lowering abrasion loss, and thereby reducing particle release into the environment. Natural oil is used instead of petroleum-based oil.

This tyre is designed to provide a higher energy efficiency due to its 20.4% lower rolling resistance than the current tyre. The new solid tyre should also have a longer lifespan as it has 26.6% lower abrasion loss. It has been built to operate 24 hours a day and has been developed for all surface conditions and intense operating environments, according to the firm.

“In creating the Ultimate Green XT, we not only considered environmental protection by using a high degree of sustainable materials but we also focused on improving performance, such as increasing energy saving of forklifts as well as extending the lifetime of the tyre,” says Prabhash Subasinghe of GRI.

This article was taken from the latest issue of CPM. For more articles like this, subscribe here.