Companion cropping could offer considerable benefits in maize, both in terms of production and soil structure, but you need the right drill and the right system. CPM reports on pioneering trials that put both to the test.

I just thought there must be a better way of doing this.

By Tom Allen-Stevens

Maize, you could argue, is a crop that’s yet to benefit from detailed UK trials work. Despite its widespread use for forage and, more recently, for anaerobic digesters, it doesn’t receive as much agronomic attention as wheat, or even barley, for example.

But this makes any trials work that is carried out on the crop all the more interesting. When this is combined with a new drill which incorporates some fairly novel features, a new way to add productivity to maize, and a big environmental benefit to boot, you get a development that could be quite intriguing.

The story starts with Rob Yardley, currently a trainee farm manager with Velcourt, who had been working as an arable operator with a farming business in the north west of England, while also studying part time at Reaseheath College.

Bit of a state

“I’d spent a lot of time as a chopper driver at maize harvest. The process often leaves the field in a bit of a state, and I’d noticed the load-bearing capacity of the soil was much better, causing less damage, where the crop was naturally weedy. I just thought there must be a better way of doing this,” he says.

Rob Yardley was keen to find ways to make the land between maize crops more productive.

Maize can sit a bit awkwardly in the rotation – it’s often harvested too late for a following winter-sown arable crop, and establishing grass can’t be successfully managed until the next spring at the earliest, leading to a sward that’s not particularly productive in its first year. The result is a field that lies bare over winter, leading to erosion and run-off, which can be exacerbated if harvest was carried out in less than ideal conditions.

“I was keen to find ways to make the land between maize crops more productive, and figured the best way to do it was to establish a second, grass crop at the same time as the maize, or undersow it.”

But this plan seemed flawed as well – if the maize faces any competition within the row at establishment, yield is knocked back considerably. By the time it’s established enough to be untroubled by a companion crop, the canopy closes in and any undersown plants will fight for light.

“I was looking for a drill that would precision-sow the maize at 75cm spacing and sow conventionally between the rows in one pass. But as far as I was aware, a drill with that ability didn’t exist,” says Rob Yardley.

So he took his search to Twitter, and it was Shaun Groom from Pöttinger UK who replied, pointing out the company’s Aerosem has a design that unites cereal and maize drilling within the same unit.

Pöttinger’s Precision Combi Seeding (PCS) system integrates individual seed drilling technology into a standard pneumatic seed drill (see panel on pxx). It’s suitable for drilling maize and is fitted with up to 10 individual seed elements for a row spacing of 37.5cm or 75cm. These units sit separate to the main pneumatic seed distribution head, that passes another seed, such as grass, or fertiliser to the other coulters at 12.5cm row spacing. A split tank transfers the seed (and/or fertiliser) to the two distribution systems.

“On the Aerosem you could also set the pressure on the maize coulters separate from the rest, so it would push the individually seeded maize down to the right depth of 50mm, but a lower pressure on the other coulters would place the grass seed at the required 5mm depth,” notes Rob Yardley.

What’s more, the distributor head offers any combination of outlets, controlled by Pöttinger’s Intelligent Distribution System (IDS). This is based on an electrical metering drive, controlled by its own terminal or via ISOBUS from the tractor terminal.

“For the maize to establish correctly without too much competition, you’d have to shut off the outlets to the coulters either side of the maize lines, as well as to the outlets that would receive the individually metered seed,” he points out.

Keen to put this system to the test, he approached Agrovista, to ask if they’d be interested in running the trials, and Reaseheath College to host them.

John Ball and Ross Barton from Agrovista took up the opportunity to investigate the potential of the system. “It was the soil erosion aspect that appealed most to us. It’s poor practice to leave soil bare over the winter and there may be legislation soon to prevent it, as there is in France. But it’s essential that any companion crop doesn’t compete with the maize, and that’s down to the design of the drill you use,” explains John Ball.

The trials were set up at Reaseheath College earlier this year (see panel on pxx) and it was Rob Yardley who drilled the plots with the Pöttinger Aerosem 3002 ADD.

“You can’t take anything away from the drill – it really was a piece of kit and did a super job of establishing the plots,” continues John Ball.

“But the biggest challenge we had was weed control. This site was intentionally chosen because it’s a high-burden weed site, and there are no pre-emergence herbicides you can use safely with grass. So that limits all weed control to post-emergence chemistry, and that’s where the limitations of some of the mixtures on trial surfaced.

“However, as it turned out, grasses may not be as vulnerable to pre-ems as we think they are – at the edge of the plots, where the pre-em treatment over the rest of the field overlapped with the outside of the trial area, we noticed the grasses we established survived the pre-em well. It’s not a recommendation and clearly needs more work, but this may overcome a potential commercial barrier for this system.”

Overall, across the 12 plots, the lesson they’ve learned so far is that it’s about finding a balance, notes Ross Barton. “We’ve shown we can get very vigorous grass growth – almost too much – or so little it was hardly worth the bother. There must be enough cover to compete with the weeds and deliver the primary objective of helping soil structure, but not so much that it competes with the maize and is difficult to harvest.”

The true value of the system won’t be fully assessed until the maize is harvested later this autumn, but John Ball is confident it has potential. “There’s no doubt you’ll end up with a more productive sward once the maize crop is cleared, and that there will be environmental benefits. It’s a question of planting the right grass mix at the right time and then finding a herbicide strategy that fits. Indications are that you want a vigorous variety if drilling into a standing crop, and a tamer one if planting at the same time,” he notes.

“But I do believe this practice will be commonplace in 4-5 years’ time – as with many of the options growers are trying that fit with Ecological Focus Area requirements, this is one that has some clear production benefits for those willing to try something new. There’s an appetite in the industry for it that will appeal to more progressive growers.”

Combination drill offers flexibility for precision seeders

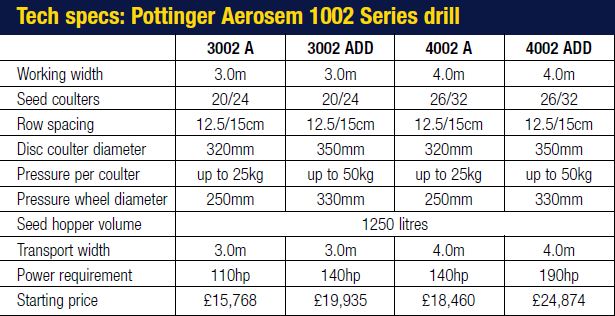

The Pöttinger Aerosem 1002 series is available in working widths of 3m and 4m. The seed drill is mounted over the rear roller of the leading tillage implement, such as a power harrow or compact disc or tined cultivator.

There’s a seed hopper of 1250 litres that sits above the mechanical or electric versions of the metering drive system. This handles seed rates from 1.5-340kg/ha at forward speeds of up to 12km/h, with the mechanical metering system driven by a land wheel on the left-hand side of the machine (the speed signal for electric metering is provided by a DGPS sensor).

A hydraulically driven fan transfers seed to the distributor head, that’s optionally operated through Pöttinger’s IDS system, for which it was awarded a silver medal at Agritechnica in 2013. This allows the operator to make adjustments to row spacing and tramline configuration via the Power Control terminal or ISOBUS-linked tractor terminal, with seedflow optimised through the distributor head. The result is a consistent number of seeds in each row and a uniform crop with seed savings of up to 6%, says Pöttinger.

Individual seed drilling is handled through the PCS technology, for which Pöttinger also received a silver medal at Agrotechnica 2013. Seed is taken from up to 400 litres of the split hopper (rather than individual hoppers) to the hydraulically driven individual seeding units, from where it’s blown to the coulter. Airflow through the precision lines is adjustable so it caters for seed of different size.

The Dual-Disc coulter delivers precisely delivered seed to the ground. The large, 350mm diameter discs push trash to the side, with a slot made by a seed-grove former. The stopper roller catches the seed emerging from the air hose and presses it down, ensuring plants are evenly spaced. Repacking and depth guidance are controlled using the standard press wheel, applying 25kg pressure or up to 50kg per coulter on the Aerosem ADD models.

The drill can be equipped with a full two rows of Dual-Disc coulters for the other, conventional seeding lines, or with two rows of single-disc or three rows of Suffolk coulters.

“The Dual-Disc coulters didn’t block up at all and there was a very even germination and consistent depth,” comments Rob Yardley. “It’s simple to convert it from a Combo-drill to a conventional seed drill – you just fold the flaps down inside the seed hopper and set the distributor head accordingly.”

The drill’s calibration was one aspect he found particularly neat. “The calibration unit runs on two tracks under the metering system, and slides out, so there’s no clambering under the drill.”

And it was among a number of design techniques Rob Yardley admires. “Whoever designed it certainly thought through the detail – it’s really well made and put together, right down to the foldable steps that sit against a special bush to keep them in place.”

The whole set up of the drill was something of a surprise for him. “I’m used to maize drilling being a contractor operation, preceded by plough and power harrow. But this is a single-pass unit, doing up to three jobs in one.”

But he does have one gripe. “For a drill of that build quality, the lighting’s awful – I was taking it on a 60-mile round trip when drilling the trials, and these days you should expect good LED lights when you’re travelling on the road.”

Trials point way to system potential

The trials at Reaseheath, established into sandy clay loam, looked at two separate timings for the companion crop to be established.

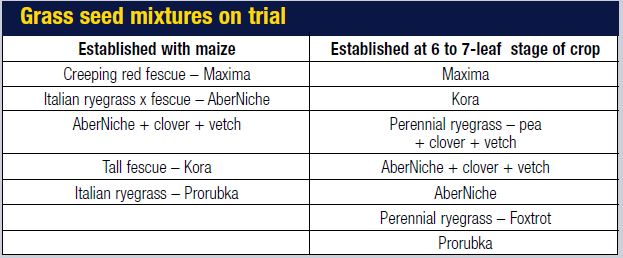

Initially, the whole site was drilled at the beginning of May at 42,000 seeds/ha with P7326, a new, early maturing hybrid from Pioneer. In five of the plots, a grass mixture was established with the Aerosem 3002 ADD at the same time, while just maize was initially planted in the other seven (see table below).

The grasses, drilled at 17kg/ha, were chosen to cover the full spectrum of vigour, points out Ross Barton. “The Italian ryegrass varieties are highly productive so potentially offer greater forage value following the maize crop. Creeping red fescue brings little benefit other than soil structure.”

At the five-leaf stage of the maize, the seven maize-only plots were over-drilled with the companion mixtures, using a specially adapted 4m precision drill. “This was the first practical difficulty we came across,” notes John Ball.

“It was hard enough to match the previous drill lines and you have to take it slow. But the drill we came back with was 1m wider than the Aerosem we’d previously used, so we did have problems on the outer row of each previous bout.”

The entire site was treated with Callisto (mesotrione) at the three-leaf stage of the maize. “Unsurprisingly, this herbicide took out any clover and vetch we’d established with the maize. The active has some residual activity, so hit the peas, clover and vetch we established later, but the clover and vetch at least seem to have survived,” he reports.

Where the grass was established with the maize, the ryegrass mixtures are too vigorous, he reckons. “The Prorubka in particular is a beast – there’s plenty of cover, but this could be competing too much with the crop and may cause problems at harvest. We thought the tall fescue would do best, but it looks a little on the weak side. Perhaps the AberNiche, that’s a fescue/ryegrass cross is the happy medium.”

The fescues never got a chance in the later established plots, however. “Here the more vigorous grass types have done better, and there’s greater prospects for adding clover and vetch that should bring additional benefits for soil structure,” concludes John Ball.