Operators looking to cut clutter in the tractor cab are turning to ISOBUS in growing numbers as more implements are equipped to support it. CPM explores this digital data and control system and reports on the in-cab solutions on offer.

It’s another step towards the autonomous revolution.

By Peter Hill

From setting up a fertiliser spreader to operating a sprayer; calibrating a seed drill to monitoring bale density; from adjusting a tractor’s hydraulics to allocating functions to a joystick – a single ISOBUS terminal can perform any number of functions that once took several individual control boxes.

And today, the more sophisticated terminals can also show remote camera images, duplicate their displays on mobile phones and tablets, and wirelessly receive prescription maps before uploading ‘as applied’ job forms to Cloud-hosted farm records.

In some cases, the operator can even let the implement perform some of the tractor control functions that he would normally do himself – think round balers and the need to stop, net the bale, open and close the tailgate and resume baling.

It’s another step towards the autonomous revolution.

Multi-function terminals in the tractor cab put ISOBUS control functions, guidance, automated implement operation and data recording at a driver’s fingertips.

ISOBUS isn’t a piece of universal software but rather a protocol devised and agreed by equipment manufacturers, and accepted by the International Standards Organisation (ISO), for digital communications between tractors and implements.

Each implement carries an electronic control unit (ECU) or job computer, a small device storing all the information needed to operate its various functions.

How to lift and lower a pick-up reel, for example; how much the shutters on a fertiliser spreader must be opened to achieve a particular application rate, with a particular material at a particular working width and speed.

It also contains the information needed for functions and settings to be displayed in the tractor cab in a more or less similar way for different implements.

Familiarity and ease of use across myriad implement tyres is the objective of that particular feature of ISOBUS.

The piece of hardware that displays this information is a virtual terminal – it collects the information it needs to create a screen display from the implement’s job computer and also from the host tractor, with sensors supplying the ‘live’ data needed.

One consequence of the universal protocol approach, however, has been the compatibility issue – software engineers left to their own interpretation of how to achieve the protocol’s goals has resulted in a fair degree of frustration as users expecting universal ‘plug and play’ experienced ‘plug and no display’ or limited functionality at best.

The machinery industry worldwide has tackled this issue through the Agricultural Industry Electronics Foundation (AEF), which refined the fledgling ISO standard and then formulated a robust testing and certification process designed to ensure the seamless compatibility of implements, tractors and in-cab devices.

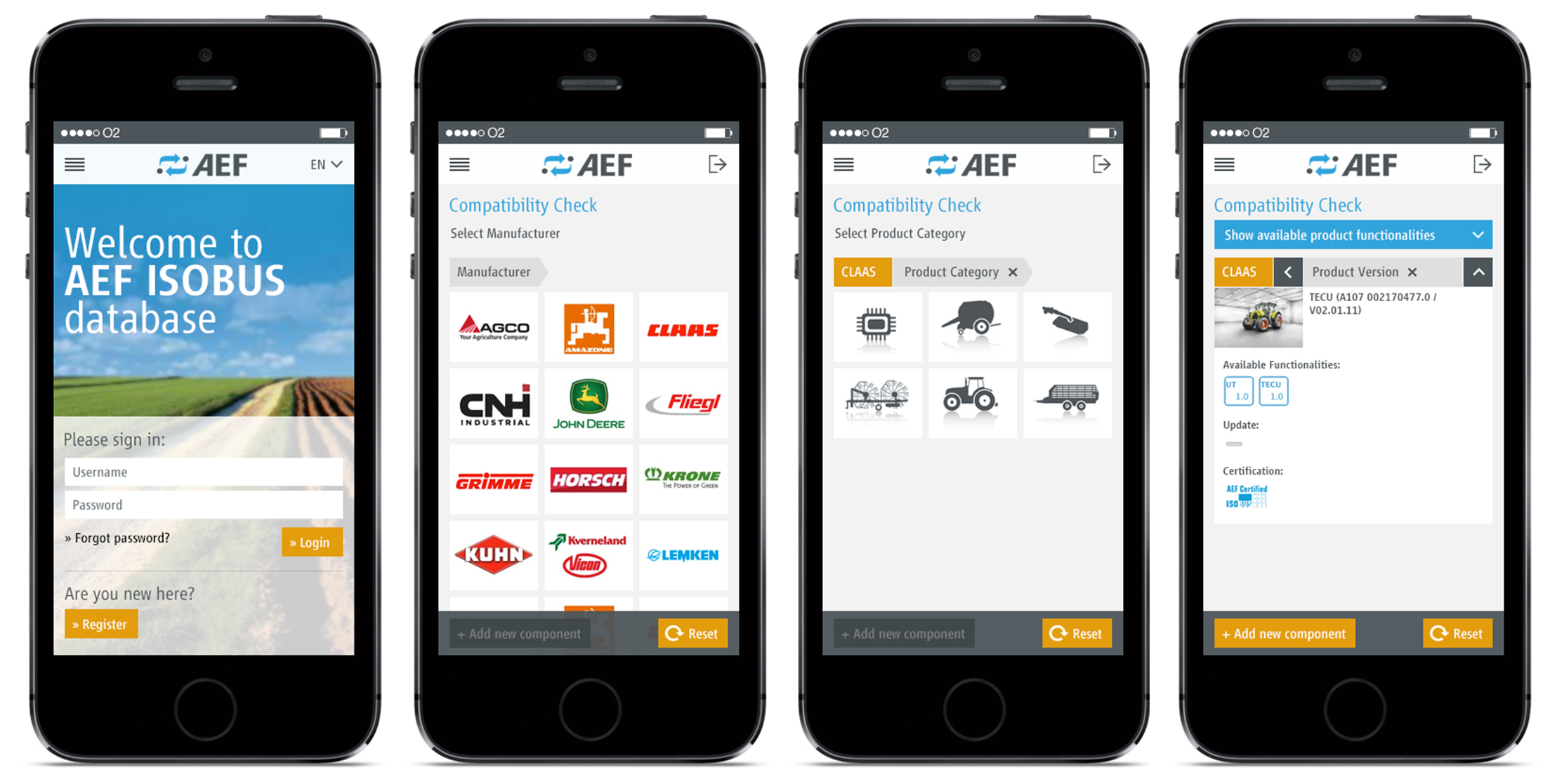

Growers can check the cross-compatibility of ISOBUS-equipped tractors, implements and in-cab devices using the AEF online database.

Testing is now carried out by five independent organisations that award AEF Certification for specific functions – such as the virtual terminal display itself, the tractor (or other vehicle) electronic control unit (ECU) and features such as section control, variable rate control and the operation of joysticks and other auxiliary control devices.

As a further check, that also helps manufacturers with new product development, the AEF organises twice-yearly Plugfest events, alternating between Europe and North America.

The Plugfest is a sort of speed-dating opportunity for electronics engineers to see for certain whether their ISOBUS devices are compatible with one another.

At the most recent event held last Nov in Germany, a record 154 electronics developers attended, plus another 80 observers, from the 211 member companies and organisations – which comprise mainly equipment manufacturers, plus suppliers of software and farm data solutions, research organisations and universities.

More recently, the AEF has gone live with an online ISOBUS database (www.aef-isobus-database.org) that end-users can now access to check cross-compatibility of devices, tractors and implements. Machinery dealers can use it to download software patches and updates.

Ten years ago, the AEF was formed by just seven international manufacturers of agricultural machinery and two trade associations. Its growth and significant funding since then is an indication that machinery makers are striving for that ‘plug-and-play’ panacea.

Manufacturer mainstays

The tractor majors are vying with implement manufacturers to offer the best and broadest solutions for growers keen to adopt ISOBUS control and the other GPS-related functions that in-cab terminals can offer.

Most continue to focus on built-in terminals that can’t be shared among several vehicles, although portable units of the type favoured by implement makers and electronic device specialists are becoming more commonplace.

John Deere

The John Deere 4640 Universal Display, for example, can be moved between tractors and harvesters.

It has tablet-like swipe functionality with run pages and the display can be laid out in several ways to suit different user preferences.

Enhancements over the 4600 model it replaces include more on-screen help and diagnostic information, a simplified Work Setup app with page-by-page navigation; and greater user customisation.

Improved documentation, latest data syncing and the ability to import new customer and product information without the risk of overwriting existing client/farm/field and guidance-line data are further benefits claimed for the unit.

A power button now allows operators to switch off or reboot the display without stopping the tractor.

Massey Ferguson

A suite of automatic control and data collection functions is available with the latest iteration of Datatronic on Massey Ferguson tractors via the fixed-installation Datatronic 5 touch-screen display.

Optional precision farming features, which are available individually or as a package, add mapping, automatic section control, variable rate application, record keeping and machine monitoring.

This 9in landscape-format terminal can be set to ‘half screen’ mode to show two functions at the same time but in full screen mode, main information is shown prominently in the centre, with activated features and functions stacked either side.

In addition, four display sections – map, tractor home, camera and ISOBUS – can be swiped in and out to quickly access all relevant information.

The display is operated by tapping or swiping the touch screen or using a scroll wheel at the side, and four hot keys on the frame – OK to confirm actions; Return; Main Screen Mode, which provides full-screen displays of tractor setting functions, guidance and camera.

ISOBUS implement control includes the ability to assign functions to a joystick or buttons on the optional MultiPad controller when fitted, to operate transmission, engine speed and hydraulic functions.

New Holland

This ISOBUS AUX-N functionality is also now available on New Holland IntelliView IV terminals thanks to an upgrade, enabling users to allocate functions to a joystick, switch box and pedal controllers.

Available on New Holland T6 and T7 series tractors, the upgrade also enables the terminal to import shape files and convert them to ISO XML format for automatic rate and section control applications on sprayers and spreaders.

This simplifies the up-loading and use of application prescriptions and reduces the risk of human error when transferring and converting data, says the manufacturer.

McCormick

McCormick Premium-specification X7 and X8 series tractors offer optional ISOBUS set-up and control functions on a non-portable 12in monitor.

As standard, the Data Screen Manager gives the driver access to numerous set-up functions covering engine and transmission performance, and lift linkage, traction control, pto and headland management functions.

When the ISOBUS digital data communications option is added, it becomes an AEF-compliant Universal Terminal as well, displaying set-up, control and monitoring information from any implement with an ISOBUS on-board job computer.

Specialist solutions

While not tailored to the livery of your preferred tractor manufacturer, specialists in agricultural electronics equipment offer plenty of choice from a range of compatible units.

Topcon

Topcon has broadened its range of offerings with the X23 ‘entry level’ portable touch-screen terminal.

In contrast to the top-end X35, which offers all manner of functionality including wireless data exchange with Cloud-based management records, the 8.4in X23 comes with just ISOBUS and visual guidance.

However, these can be joined by additional functions as and when users want them by paying an ‘unlock’ fee for hands-free auto steering guidance and sprayer/spreader control with ‘as-applied’ graphics and data records.

Auto section-control with up to 10 segments for sprayers and spreaders is also available, along with variable rate application of seed, sprays and fertilisers using prescription maps.

Like other terminals in Topcon’s X series, the new X23 runs the company’s Horizon icon-based operating system, which allows users to create individual display layouts and screens.

Müller-Elektronik

The Smart 430 is another ‘entry-level’ ISOBUS terminal, this time from Müller-Elektronik.

It comes with a 4.3in colour display showing the typical functions available with implements equipped with an ISOBUS-compliant job computer but unlike the touch-screen operation of larger units, the Smart 430 is operated using soft-keys and menu buttons arranged around the perimeter of the display.

On the back of the device, there are two M12 plug sockets for connecting the tractor CAN-BUS, as well as sensor inputs for recording the working speed and the working position.

The unit has AEF-certified functionality as an ISOBUS Universal Terminal (UT) and Auxiliary Control (AUX-N), which means it can be connected to compliant control devices such as a joystick with user-allocated axis and button functions.

Trimble

Trimble’s 10.1in colour screen GFX-750 is aimed at mixed fleet owners who can use it with most tractor makes as an ISOBUS Universal Terminal to communicate with compliant implements, and also a guidance display that can also measure and record such things as application rate and compare it with a user-defined target.

Using Trimble’s Field-IQ software on the Android operating system means it can also communicate with implements without using the ISOBUS protocol.

The GFX-750 package, which Trimble says will suit farmers new to precision farming technologies, includes a NAV-900 guidance controller with triple-frequency multi-constellation GNSS receiver to work with a number of different guidance systems and correction signals to provide robust signal availability, especially in hilly terrain.

Consortium consoles

The latest ISOBUS terminal from Competence Center ISOBUS, the electronics joint venture formed by a number of leading agricultural implement manufacturers, has software enabling information from two implements – mounted front and rear, for example, can be displayed simultaneously.

The CCI 1200 has a 12.1in screen, which makes it significantly larger than the current 8.4in CCI 100 and CCI 200 terminals, allowing greater flexibility in the display layout.

Users can organise the display in different ways; for example, showing two applications next to each other, such as a remote camera feed or map view alongside an implement display.

Also, the displays can be arranged in either portrait or landscape format and a ‘maxi-view’ option is available providing extra-large screen keys for easier use when operating a tractor over a rough surface.

Multi-touch operation in combination with new menu navigation is said to make the device more like a smartphone to use, with a reduced number of clicks needed to select functions.

Apps for automatic section and variable rate control are available and there’s in-built capability for switching tramline equipment according to satellite-based positioning and variable rate prescription maps in ISO XML or Shape format.

Spread ability

Kverneland has extended availability of its fertiliser spreading set-up app to the compact version of the IsoMatch Tellus in-cab terminal.

The AutosetApp software – previously available only on the full-size twin display Tellus – provides automatic setting up of Exacta CL-EW and TL spreaders equipped with weigh cells once the key parameters have been entered by the operator.

The IsoMatch Tellus GO terminal has a 7in touch screen display, with data entered also by hard keys and a dial at one side, and as standard provides visual guidance, support for external variable rate devices and data exchange via USB memory stick in addition to ISOBUS functionality.

Users can also purchase a license to unlock GEOcontrol variable rate and working width section control.

Cab tablet

Using a tablet computer as an ISOBUS display terminal is an alternative to a dedicated unit with the Claas ‘EASY on board’ Universal Terminal App.

This enables an Apple iPad running iOS8 or later to operate as an ISOBUS display with compliant implements, and includes the AUX-N facility to assign certain implement control functions to the ‘F’ keys on a Claas tractor’s joystick.

Communication between the implement and the iPad takes place over a wireless connection via an adapter connected to the in-cab ISOBUS socket of the tractor.