A year on since the initial launch of the “second generation” of Lexion combines, Claas has added two new straw walker ranges to its offering for UK growers. CPM looks at the latest additions to the fleet.

The new threshing system is what sets it apart from anything else on the market.

By Charlotte Cunningham

It’s been just over a year since Claas unveiled a major overhaul to its Lexion range of combines.

With big aims to breathe new life into the much-loved Lexions, four new ranges were debuted as part of this “second generation”.

But not all were immediately available in the UK. Two hybrids were launched for harvest 2020, but those in the market for straw walker types had to hang tight for another year.

Claas UK decided to launch the hybrid ranges first, followed by the straw walkers, as part of a step-launch programme

Now, 12 months later, Adam Hayward, product manager at Claas UK says this strategic approach has paid off. “Because we’ve brought in such radical changes within these new machines, there were a huge number of considerations to factor in before launching them. Namely, ensuring our service and parts team were up to speed and confident with exactly how everything worked.

“We made the decision very early on in the planning process that we’d launch the hybrid ranges first, followed by the straw walkers, as part of a step-launch programme, so we could ensure the level of service customers received wouldn’t falter.

“The new straw walker series are very important launches for us, and we needed the correct strategy to get the most out of them.”

Though anecdotally there has been some talk over the relevance of straw walkers in recent years, the market is actually enjoying a resurgence in interest right now, notes Adam. “We’re seeing an increasing number of customers wanting to bale and keep straw. However, they also want the output.

“In the past, ticking the two boxes has been somewhat of a trade-off, so this was something we factored into the design process, and have been able to deliver within the new straw walkers.”

Now, looking to harvest 2021 and with an expertly trained team waiting in the wings, Claas has unveiled the detail of its latest addition to the Lexion fleet – the 6000 and 5000 range of straw walker combine harvesters.

So what exactly is it about this new range that sets it apart from its predecessor?

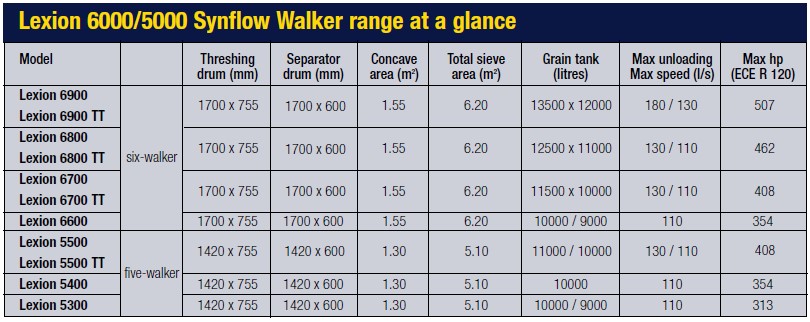

“As part of the natural evolution of the Claas Lexion range, the introduction of the new second generation Lexion 6000 and 5000 range of straw-walkers combine harvesters sees not only a considerable expansion in models available, but also the introduction of a host of new features all designed to provide a further increase in output and efficiency,” explains Adam.

While the whole concept has been redesigned from the ground up, perhaps one of the biggest changes is the completely new threshing system.

The APS threshing system is nothing new and has been an integral part of Lexion’s design and performance since it was introduced 25 years ago. But the traditional system has been given an upgrade to boost performance further. “The development of the new APS Synflow Walker system takes the threshing and separation performance from the Lexion 6000/5000 to a new level,” says Adam. “This is achieved by bringing together the accelerated crop flow provided by the APS system but adding to this an additional separator drum after the threshing drum.”

Central to the all-new threshing system is a 755mm-diameter drum, fitted with 10 rasp bars, coming in at a rather impressive 26% larger than the 600mm drum on the Lexion 600 range.

Behind this is the new 600mm-diameter separator drum that provides additional gentle separation of grain from the straw.

The greater diameter of the main threshing and separating drums has the benefit that the concave wrap angle is shallower at 132° and 116° respectively, highlights Adam. “As a result, straw flow through the APS Synflow Walker system is flatter and gentler, resulting in improved straw quality, but load on the threshing system is reduced, so saving power and fuel.”

The shallower angles also mean that the main concave area has been considerably increased, he adds. “At 1.30m2, the 1420mm-wide unit fitted to the five-walker Lexion 5000 now has a larger concave area than the current largest Lexion 670 six-walker model (1.22m2) while in the 1700mm-wide unit fitted to Lexion 6000 models it’s a massive 1.55m2.”

Due to the wider diameter and higher centrifugal speed of the rasp bars, to maintain velocity this means that drum speed has been reduced and is now infinitely variable using CEBIS from 330-930rpm. Drum speed is also synchronised across all four drums, notes Adam.

For optimum performance across all crop types and conditions, the main concaves are easily infinitely adjusted hydraulically using CEBIS – Claas’ on-board information hub. “This provides both parallel and synchronised adjustment of the pre-concave, threshing concave and separator concaves, so ensuring an even flow of material through the threshing system.

“Where it’s necessary to change the concaves, for instance when harvesting beans, this is quickly and easily done and 40% of the main concave can be pulled out sideways.

“Where greater threshing intensity is needed, for instance in difficult to thresh crops or for de-awning barley, the APS Synflow Walker system incorporates an additional pivoting concave bar located between the pre-separation concave and the main concave, again engaged hydraulically using CEBIS.

“For me, this new threshing system is what sets it apart from anything else on the market. Featuring a larger threshing drum and now the addition of a secondary separator, that’s where we’re getting extra performance from the machine.”

To handle this increased throughput, grain tank capacity ranges from 9000 litres on the smallest Lexion 5300 to 13,500 litres on the Lexion 6900.

What’s more, growers also have the option of seven different unloading augers with lengths up to 12m, which have a forward pivot angle of 105° for improved visibility. “Depending on model and auger diameter, the maximum emptying speed is 180 l/sec on the Lexion 6900, enabling its 13,800-litre tank to be emptied in just 75 secs,” says Adam. “If necessary, the unloading speed can be halved to 90 l/sec for topping off trailers.”

In addition to the upgraded threshing system, the Lexion 6000/5000 also features Claas’ Jet Stream cleaning system on all models – a feature that was previously only seen on the hybrid types. “Model dependent, the six or eight-turbine fan, venting through a dual straw-walker and a long airflow equalisation channel, provide intensive pre-cleaning of the grain. The sieves and fan are adjusted electrically from the cab,” he adds.

At the heart of the 6000/5000 are either MAN or Mercedes-Benz engines with power outputs ranging from 313hp on the smallest Lexion 5300, right up to 507hp for the largest Lexion 6900.

With an aim to keep a lid on costs through optimum fuel efficiency and economy, Dynamic Power is another new feature available on all Lexion 6000/5000 models, highlights Adam. “Dynamic power is an intelligent engine management system which automatically adjusts engine power output relative to load. Our Dynamic Cooling variable fan cooling is also standard on all models, which draws clean air in from above the combine and blows it out down over the sides of the machine.”

Drawing inspiration from that seen in the Jaguar forage harvest range, operators also benefit from a completely new drive system.

According to Claas, this ensures a more positive, smooth engagement of the threshing and auger systems, while a new clutch system is used to engage and tension the belts, resulting in improved belt life. “The straight-line design of the drive system results in lower power loss and has reduced the number of belts,” says Adam. “This not only eases maintenance but has also resulted in fewer ledges and angles on which dust can gather, so improving overall cleanliness.”

Turning focus to the whizzy gadgets and gizmos on board, automation has been embedded through various elements of the design.

Examples of this include the new pivoting concave bar, synchronised drum speed and concave adjustment systems which are fully integrated into Claas’ CEMOS Auto Threshing, and uses information from the grain quality camera and Quantimeter to automatically adjust the concave settings and drum speed, says Adam. “Where CEMOS Auto Cleaning is fitted this will automatically adjust the Jet Stream fan speed and the upper and lower sieve settings. All this information is also now fully integrated into the new CEBIS touchscreen terminal.”

Sensors in the new APS Synflow Walker and secondary separation system are also used by Auto Crop Flow to monitor flow and load through the Lexion and to automatically restrict crop entering the combine should it detect a potential blockage, so allowing the operator to confidently push the combine without the risk of overloading it, he adds.

No pub yields in sight…

More so than ever, squeezing every last bit of grain from the crop is crucial – particularly during seasons like this year’s where crops are somewhat thin on the ground for many.

To help operators get a better handle of exactly what’s coming off every field, the Lexion 6000/5000 range also incorporates the latest Quantimeter yield measuring system, which uses a pressure cell in the grain elevator delivery point to accurately record yield without needing the thousand grain weight. “Not only is this far more accurate and robust, but it only needs calibrating once a year for each crop type. It’s also fully compatible with Telematics for yield mapping and record keeping,” says Adam.

Engine updates for the Axion 800 range

As well as the launch of the new combine ranges, Claas recently announced updates to the Axion 800 range – which has become the latest in the CL tractor line up to make the move to being powered by a Stage V compliant engine.

On top of the engine update, a number of specification upgrades have also been made. “Maximum power outputs from the FPT engines used by the five-model range remain the same, rising from 205hp for the Axion 800 to 295hp for the Axion 870, but as part of the move to Stage V there’s a slight increase in the torque curve, so giving more low down torque,” says Steffan Kurtz, product marketing manager at Claas UK.

From the outside, these new models wear the same detailing on the bonnet as seen on the Arion 600/500 range that was introduced last year. However, internally, there are now a number of new features to increase both functionality and operator comfort.

“As with the Arion, all CEBIS Touch equipped machines now come with ISOBUS UT as standard, allowing it to be used as a universal implement control terminal,” notes Steffan.

However, a separate terminal, such as the CLAAS S10, will still be needed for more advance ISOBUS functions such as TC Geo for mapping and variable applications or TC SC for section control.

Other new features within the CEBIS Touch terminal include a USB socket for importing/exporting data, an upgrade to the implement settings and storage function, a reading for the average wheelslip, the ability to view external cameras through the CEBIS screen and greater customisation of the screen layout to suit individual operator preferences, he adds.

In addition to the standard hydraulic flow of 110 l/min – with an option of 150 l/min – there’s now a further option of a 205 l/min hydraulic system, points out Steffan. “An engine speed memo button can also now be linked to the external PTO button through CEBIS, and the PTO system itself now features an uprated seven-plate PTO clutch for greater durability with heavy load implement.

In a bid to boost operator comfort, a Grammer EVO Dual Motion seat is also now available, which is heated, ventilated, and comes with a tilting headrest, he adds. “A nice new feature for the cabin is an option of a rear tinted window. As standard twin brake pedals are now fitted across the Axion 800 range, as well as LED flashing lights and a flexible bottom step.”