The Lexion range of combines has been overhauled with the range-topping 8900 the biggest available for harvest 2020. CPM travels to its launch in France.

What we launch today is a truly new machine.

By Tom Allen-Stevens

By any stretch of the imagination, it’s an impressive sight. At first there are just four blobs of light between the blue, cloudless evening sky and the ripe, golden wheat.

The hum of the harvest draws ever closer, joined as it does by the buzz of drones, launched to capture the moment, while around 100 of the world’s press jostle in to claim prime position for the working shot at Nourray, near Le Mans in north-west France.

The four new ranges of Lexion represent the biggest overhaul in the combine’s 25-year history.

This is the launch of what Claas is calling the second generation of its Lexion combine. There are four new ranges, two of which are hybrids, coming to the UK for harvest 2020, with the smaller straw-walker versions due to arrive in the following year.

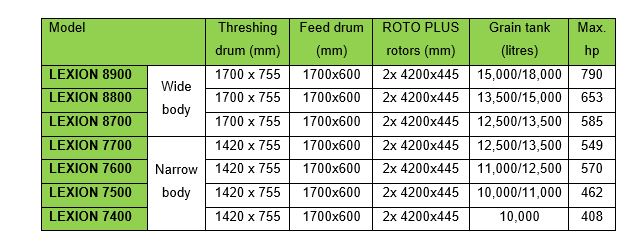

These include three models in a new 8000 series. The 8900 now tops the fleet with a 790hp engine and grain tank of 18,000 litres. Complete with a new 13.8m header (see panel), it’s the largest and strongest combine in the world, claims Claas. The new 7700 matches the throughput of the current fleet-topping Lexion 780, which is replaced with the new 8800.

“When we launched the Lexion 480 almost 25 years ago, it set a new benchmark for high performance in combines,” says Claas board member and CEO of the company’s grain business unit Jan-Hendrik Mohr. “It became machine of the year, and iterations since have stood for a unique throughput and reliability. The 600 series is unmatched in terms of productivity, and the 700 series has attracted multiple awards.

“What we launch today is a truly new machine, with all new threshing drum and all new engine. Ten years in development and with over 6000 hours of endurance testing, never before has Claas invested so much money and effort into a new combine. Half of the current Lexions are already the biggest combines in their class. Now the 8900 is capable of harvesting crop at a rate that would produce enough grain for one million half-litre bottles of beer every hour.”

On a like-for-like basis with current models, there’s a step-up of around 10%, claims combine specialist Christian Schulte – the 8700 delivers 10% more output than the popular Lexion 770, for example. So where does this extra productivity come from?

“At the heart of the Lexion Hybrid has been the APS threshing system and it has been the development of the new APS Synflow that’s the key to this increase in harvesting capacity,” he says. “Other new features include more powerful engines, bigger grain tanks, larger concaves, greater separation control, a new drive system and faster unloading.”

The APS Synflow primary system has a new 755mm diameter threshing drum, which is some 26% larger than the current 600mm drum found on the Lexion 780, and is fitted with ten rasp bars, compared with eight. Alongside this is a new 600mm diameter feed drum – 57% wider than before.

The larger drum can run slower to maintain the same rasp bar velocity – 550rpm compared with 750rpm – and speed is infinitely variable from 330-930rpm, using Claas’ CEBIS on-board control system. “All drums are fully synchronised so there’s a very even and reliable crop flow,” says Christian.

The changes mean separation area has been considerably increased. The operator also has greater control over the threshing area and can engage the main concave flaps hydraulically from the cab. There’s also a new hydraulic pivoting concave bar between the pre-separation concave and main concave that can be engaged via CEBIS in harder-to-thresh crops.

The nose separating crop flow into the two Roto Plus rotors has been extended and the angle of the rotors themselves has been flattened for higher throughput and reduced straw damage. The rotor concaves have also been redesigned and the number of rotor cover plates has been increased.

The higher throughput of the new Lexions is fed to a bigger grain tank – up to 18,000 litres on the 8900. The maximum tank unloading speed is now 180 l/sec with an unloading time of just 100 seconds. The pivot angle of the unloading auger has been changed to 105°, making it easier to see from the cab.

Either a MAN or Mercedes-Benz engine provides the power, with outputs ranging to a new high of 790hp for the flagship 8900, supplied by a six-pot MAN D42 16.2-litre model. Claas’ Dynamic Power engine management system automatically adjusts power output relative to load, while Dynamic Cooling varies the fan which draws clean air in from above the combine and blows it out down over the sides of the machine.

A new drive system, based on that used in the Jaguar forage harvester, brings a more positive, smooth engagement of the threshing and auger systems, says Christian, while a new clutch system engages and tensions the belts, improving belt life. “The straight-line design of the drive system results in lower power loss and has reduced the number of belts,” he adds.

Whether on Terra Tracs or wheels, all new Lexion 8000/7000 models are capable of travelling at 40km/h. Wheeled machines can have larger tyre sizes, going up to 42in and a diameter of 2.15m on the front axle and 34in, 1.75m diameter on the rear.

A new, larger cab has improved sound proofing and a larger grain tank window. All the main functions are controlled using the CMotion control, which incorporates a new favourites management system, and the CEBIS touchscreen terminal.

This gives the operator three different ways of adjusting the main machine settings – through the CEBIS terminal, via the rotary push switch on the CEBIS control panel, or via direct switches on the new armrest which open a dialogue box in CEBIS to show the level of adjustment. The armrest also includes radio and telephone controls and a USB charger socket.

The new Quantimeter yield measuring system takes its information from a pressure cell, making it more accurate and robust than on the current models, says Christian. It only needs to be calibrated once a year for each crop type and is also fully compatible with Claas Telematics.

Unlike some new combines on the market, the Lexion keeps its steering wheel, but the Laserpilot automatic steering system, originally launched in 1999, has been replaced with a new Field Scanner. Now mounted on the top of the cab, this uses a radar scanner originally developed by Audi. Unlike Laserpilot which can only scan in one direction, Field Scanner looks over an arc of 145° to both left and right, and can recognise both standing crops higher than 10cm and tramlines.

“The new Lexion’s been redesigned from the ground up and tested to ensure it works reliably in all conditions,” notes Claas UK’s Adam Hayward. “Currently there are about 220 pre-series machines working across 10 countries worldwide, including in the UK. We currently sell about 230 Lexion combines in the UK per year, the vast majority hybrids, so we’re expecting a lot of interest in the new models.”

The new Lexion Synflow Hybrid range

New cutterbar for specialist and low-lying crops

A complete new range of draper-type cutterbars have come in for use with the 2020 season Lexion combines. What’s more, there’s now a wider 13.8m version of the popular Vario cutterbar.

The new Convio cutterbar is available in five working widths from 7.70-13.8m. There’s a rigid version, suitable for cereals and similar tall crops, while the Convio Flex has a flexible knife and cutterbar for crops close to the ground such as peas and herbage seed. This allows the knife to moving over a range of 225mm (+90mm to -135mm).

Both cutterbars use the Auto Contour system which uses sensors to follow the ground contours, while Active Float allows the operator to alter the ground pressure of the cutterbar depending on ground conditions. The Flex has four operating modes, depending on the degree of automation required when tackling laid crops.

A new design of reel with an adjustable cam track allows the reel to be set so that it picks the crop up ahead of the knife bar. Hydraulically driven, it features an automatic torque control system that adjusts speed dependent on the harvesting conditions. Automatic Belt Speed adjusts the belt relative to the forward speed of the combine to ensure an even crop flow.

The new 13.8m-wide version of the Vario cutterbar matches the capacity of the top-of-the-range Lexions, and features a split knife, reel and 660mm header auger. The header auger and knife are both mechanically driven from each side through a gearbox.