The results of new pre-emergence application trials, carried out by Syngenta have highlighted the importance of boom height, forward speed, water volume and nozzle selection to target soil surface.

CPM went behind the scenes to take a look at exactly what the data has shown, and how growers can benefit practically from the research.

By Charlotte Cunningham

Optimising nozzle choice is not a new concept, and most growers will be aware of the influence selection can have on the subsequent crop performance.

However, new research from crop protection firm, Syngenta, has shown how nozzle choice has a fundamental effect on hitting the target and delivering effective coverage of the soil surface to get the best control from all pre-emergence applications.

Nozzle choice will have a fundamental effect on hitting the target and delivering effective coverage of the soil surface to get the best control from all pre-emergence applications, reports James Thomas.

Residual herbicides principally work via root and shoot activity, explains Syngenta application specialist James Thomas. “Ensuring an even distribution of herbicide over the soil surface will improve your chances of controlling emerging grass and broadleaf weeds.”

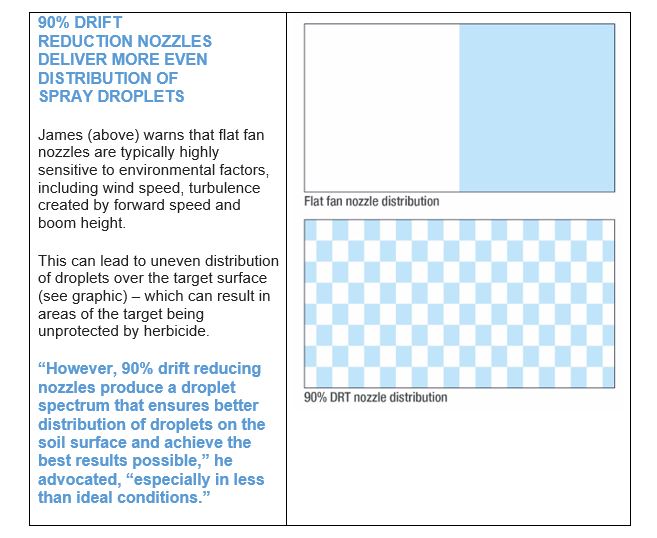

According to James, flat fan nozzles can be highly sensitive to environmental factors like wind speed and turbulence created by forward speed and boom height. “This can lead to uneven distribution of droplets over the target surface – which can result in areas of the target being unprotected by herbicide.”

However, there could be a solution. Results of new application trials at the Syngenta Barton Black-grass Focus Site have shown that 90% drift reduction nozzles delivered consistently better results, compared with flat fan nozzles – especially in marginal spray conditions.

“This type of nozzle produces a droplet spectrum that ensures better distribution of droplets on the soil surface and achieves the best results possible, especially in less than ideal conditions,” he explains.

The trials showed that using 90% drift reduction nozzles — operated at 50 cm boom height, at 12km/h to apply 200 litres/ha — delivered 10% improvement in blackgrass control, compared to spraying with flat fan nozzles under the same conditions, operating at one metre boom height at 16km/h to apply 100 litres/ha.

Further research at the Syngenta Ryegrass Focus Site, in Yorks, demonstrated best practice using 90% DRT nozzles delivering an even greater 15% improvement in control — compared to compromised performance with flat fan nozzles.

“The key challenge for growers and operators is that even within the constraints of following best practice, there are a limited number of ideal spray days for flat fan application,” explains James.

Watch the latest Spray Dudes video for Top Tips to get the measure of wind

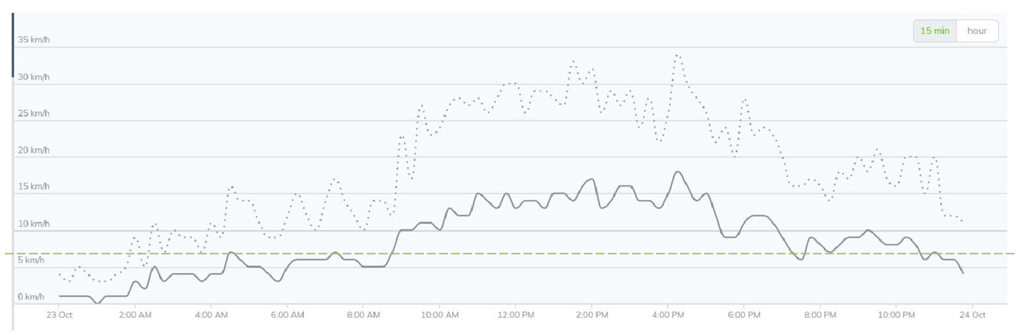

““Even on a good spray day there are frequently large variations in wind speed resulting from gusts.

“Weather station monitoring at Barton last autumn highlighted that on a near ideal spray day — which had an average wind speed of 4km/h — there were only 2.25 hours where wind gusts were below 7.2km/h.” he notes.