Omex Agriculture – the UK’s largest, family run, independent manufacturer of liquid fertilisers – has sponsored this edition of Tech Talk on the benefits of ‘Going Liquid’.

Deciding whether to sprinkle or squirt is a very personal decision when it comes to fertiliser application. CPM explores the reasons why growers may decide to ditch the fertiliser spreader and go liquid.

The real winner for liquid over granular fertiliser is in logistics and time management.

By Lucy de la Pasture

Liquid or granular? It’s a question most growers will have considered at some point. There’s been a steady growth in the liquid fertiliser market in the UK, but in recent years there’s evidence that a growing number are shifting their fertiliser application to liquid. A recent survey carried out by ADAS has highlighted some of the reasons behind the change.

Operating nozzles within the correct pressure range to produce the recommended droplet size will mitigate the risk of scorch occurring.

CPM talks to Omex agronomist Andy Eccles about the results and finds out more about the advantages and disadvantages of a liquid fertiliser system.

How does accuracy compare?

Minimising any nitrogen (N) and sulphur (S) that’s ‘wasted’ during application is important for both environmental and economic reasons. It’s not just about making sure the fertiliser doesn’t land on non-cropped areas, it’s important to deliver the right amount to each plant and in the correct ratio so that the crop can use the nutrients most efficiently.

Applying fertiliser in the liquid form makes it easier to get these key things right, particularly as growers move to wider tramlines. For instance, if the tramlines are running obliquely to the headlands then it’s simple to switch sections of the boom on or off to avoid over or under-dosing, and this also gives accuracy at the field margins.

In contrast, granular spreaders run on an over-lap pattern and, even though deflectors clearly help on the margins, it’s not possible to directly turn the spreader off on parts of the field where it’s not needed. This is easily done with liquid supplied vertically from a boom.

Solid fertilisers containing N and S are often a blend and may segregate or not feed through the hopper evenly. In a liquid NS blend the application is more accurate, with every fertiliser droplet delivering exactly the same ratio of N:S.

The ADAS survey cited that application rate control was a key reason for using a liquid rather than granular fertiliser. The controller in the sprayer is easy to set up and the operator always knows the rate being applied/ha.

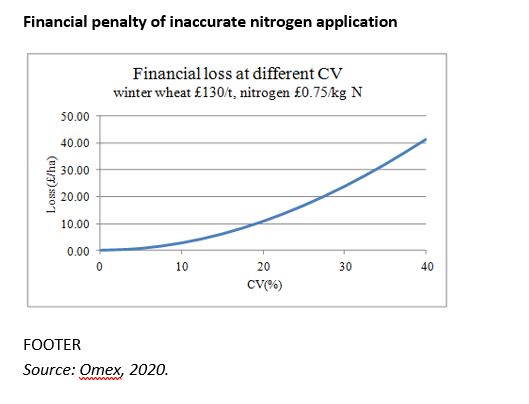

It’s also much easier to maintain consistent application over time with a sprayer, which on average runs at a co-efficient of variation of 5%. For a spreader this tends to be 8-10% and it’s more sensitive to ‘going off’ in use. What’s more the most recent copy of the British Survey of Fertiliser Practice shows that 20% of spreaders are never tray tested and 40% are tested only once per year.

Is it more efficient?

Liquid fertiliser enters the soil and diffuses more quickly than a granule which, together with its more accurate dosing, means plants have the best opportunity to make efficient use of the nutrients applied.

But the real winner for liquid over granular fertiliser is in logistics and time management, and this was highlighted by growers in the ADAS survey as one of the key factors which prompted a change in application practice.

Adopting a liquid system allows growers to make best use of their sprayer, with one machine being utilised for two jobs. Sometimes this is perceived as a disadvantage, but the reality is that application of liquid fertiliser is often possible at times when conditions aren’t suitable for the application of agrochemicals – when it’s too windy or on a showery day.

The liquid system doesn’t require handling equipment for heavy bags and there’s less wastage, with a small amount of granular product always trapped in corners of the bags when empty. Another plus is that any unused liquid can be returned to the storage tank once application is complete, whereas for solid fertiliser, the spreader has to run until it’s empty.

What are the environmental benefits?

The government’s new 25-year Environment Plan has a keen focus on improving air and water quality, and plants and animals which are thriving in a cleaner, greener country.

Liquid offers the greatest precision at field margins, and where wildlife or pollinator strips are running within fields, so that higher input systems can safely run alongside more natural ecosystems without causing them any harm.

The use of urease and nitrification inhibitors, such as Didin (contains DCD), can significantly improve the uptake of nitrogen by the plant. Didin has been available for many years and its original purpose was to allow the full season’s nitrogen to be applied in one early pass, saving time and costs by reducing the number of applications required.

More recently it’s been identified as a potential tool to reducing ammonia and nitrous oxide losses to the atmosphere and to reduce nitrate losses from leaching into groundwater. It does this by regulating a steady release of nitrate fertiliser as the plant needs it, creating a stronger, healthier plant that’s better able to cope with stresses, such as waterlogging or drought.

As well as the ability to get the nutrient to their target, liquid has no packaging waste to dispose of – another environmental plus.

Are there downsides?

The biggest concern growers have using liquid fertiliser is scorch, but it’s a risk that can be easily mitigated. Scorch happens when the plant takes up too much nitrogen and the tissues become over-loaded and certain environmental conditions or application techniques increase the chances of scorch.

While fertiliser can be applied in windier conditions than agchem, when the crop gets taller later in the spring, wind causes leaves to rub together and removes leaf wax. This increases the amount of nutrients that are absorbed by leaves and can result in scorch. Avoiding application in or after a period of windy conditions will minimise the risk of scorch. Enough gentle rain so that the liquid is washed off the leaf will also reduce the risk of scorch, while a damp crop from heavy dew or drizzle will increase the risk.

Another way of avoiding the risk of scorch is to apply the crop’s requirement of liquid nitrogen with Didin in early season. According to the ADAS survey, where scorch did occur, there was no effect on the yield of the crop.

Making sure the correct dribble bar or nozzle is fitted and operated within the correct pressure range to produce the appropriate droplet size will also mitigate any risk of scorch occurring – large droplets will readily bounce off the crop onto the soil, whereas smaller droplets will be more likely to remain on the foliage.

Liquid fertiliser is more corrosive than agrochemical mixtures, so this is something to take into account as a part of sprayer maintenance. It has no effect on paintwork, but any exposed steel will benefit from a regular application of grease after washing down to prevent rusting.

What about precision farming?

Sprayers are ideal for precision and variable rate fertiliser application is an established technique. Special variable rate nozzles and bars are widely available and contain a flexible restrictor which allows more liquid to be released as pressure increases.

Altek have taken precision technology further by designing a ‘smart’ nozzle cluster, where each nozzle can be controlled individually and independently along the length of the sprayer boom, giving the potential to infinitely vary fertiliser rates every 50cm across the field.

Liquid fertilisers are much easier to tailor to match the requirement of crops. In particular, more N:S ratios are available which suits growers who want to apply S with every application of N, and this was another factor for growers choosing liquid that was highlighted within the ADAS survey.

What are the logistical differences?

One of the major advantages of applying liquid is that a sprayer tank will cover a larger area than a spreader before needing to refill, increasing work rates.

1m3 of liquid N contains more N than the granular options, 390kg N, compared with the same volume of ammonium nitrate (AN) and urea, which both contain around 345 kg N. Although urea is 46% N compared with AN 34.5% N, urea is often lighter and leaves more air spaces which means it takes up more space in the spreader hopper.

An average spreader hopper contains 2500 litres (863 kg N) and the average sprayer tank 3500 litres (1,365 kg N), so a liquid load will contain an extra 500kg of N which is sufficient to cover an extra 10ha when applied at 50kgN/ha.

Storage tanks are generally supplied by liquid fertiliser manufacturers as part of the deal, the only requirement from Omex (since June 2019) is that the tank site is bunded before installation. Omex is also in the process of reviewing older installations that weren’t bunded to identify higher-risk sites that may benefit from upgrading.

Tanks are filled pre-season and where tanks have telemetry fitted, re-filling is an automatic process. For tanks without telemetry, there’s up to 72-hours lead-time for delivery in the busiest times.

As with most decisions in life, one system won’t fit all farm businesses, but where farmers are looking for accurate nitrogen (and sulphur) application at wide bout widths, with a focus on protecting field margins, liquids may have some room for further growth.

Top Tips: benefits of liquid fertiliser

- Enhanced precision – scope to vary rate and apply vertically from the boom brings agronomic and environmental benefits, limiting under or over-application.

- Accuracy of application – each droplet contains the same amount of nutrient(s).

- Logistical advantages – less time is spent filling up, more spray days and less space is required for storage.

More spray days from liquid switch

Yorkshire arable farmer and contractor Nigel Phillips uses liquid fertiliser and slow-release nitrogen technology to boost milling wheat and malting barley quality, improve his environmental footprint and free up time to build his expanding contract spraying business.

He reckons applying liquid fertiliser with Didin has significantly increased his available spray days by nearly a third. Nigel farms about 60ha near Northallerton, which supports continuous winter wheat and spring barley, with stubble turnips breaking up the rotation on his spring barley land.

The milling wheat receives 225kgN/ha. “It’s a nutrient-hungry crop, which needs high nitrogen input to keep the protein levels up,” he says.

“The first time we used Omex liquid fertiliser, we just used conventional mixtures and sometimes had some scorch, but Didin stopped the problem and we’ve used it ever since. It means only one application is needed to provide a crop’s entire nitrogen requirement, which was very appealing.”

The impact on Nigel’s farming system has been considerable, with an average yield for milling wheat yields at 8.64 t/ha and peaking at 10.62 t/ha. He also applies foliar Protein Plus in the first week of July to help achieve 13% protein.

He argues that the extra cost of Didin is offset by the additional application costs required where a granular or liquid fertiliser is used on a split dose application system. He’s just moved to suspension fertilisers in the autumn, which he believes will free up more time, improve application accuracy, and reduce storage and waste. His granular spreader is now redundant and will be sold or scrapped.

“Switching to Omex suspension fertiliser should address some indices inconsistencies,” he says. “Applications can be tailored to each field rather than a blanket application of potash and phosphate across a field.

“On some of my customers wetter land, we always include Didin to reduce the number of in-season land movements, which has the potential to turn around the profitability on that land without compromising soil structure from compaction and rutting. It’s been a game changer for some of these growers,” he says.

Sponsor message

In recent years the popularity of liquid fertilisers has soared, with more and more farmers turning to the liquid alternative. Omex is committed to improving Nitrogen Fertiliser Use Efficiency (NFUE), aka ‘how well the crop utilises the nitrogen in the fertiliser applied.’

The use of nitrification and urease inhibitors can significantly improve the uptake of nitrogen by the plant, by regulating a steady release of the fertiliser as the plant needs it and reducing losses to the atmosphere or by leaching. This creates a stronger, healthier plant better able to cope with stresses such as drought.

Didin is formulated with nitrification and urease inhibitors which control the release of nitrate nitrogen and reduce the risk of ammonia and nitrous oxide emissions, increasing yields, reducing application costs and simplifying the nitrogen management of the crop. It allows the full season’s nitrogen requirement to be applied in one early pass, saving time and costs by reducing the number of applications required.