Pre-em herbicides have become the foundation for blackgrass control but can provide very variable levels of control. CPM asks for some tips in what may prove a less favourable season for pre-ems than last.

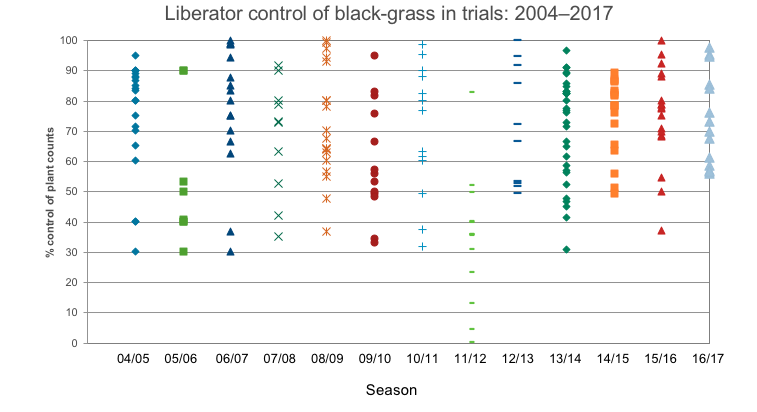

It’s possible to achieve control of up to 80-90% from Liberator alone, but in a very dry season it could be much lower.

By Lucy de la Pasture and Rob Jones

In a good year, the pre-emergence herbicide application can make the largest chemical contribution to blackgrass control. But in practice there’s often variability in their performance in different seasons – mainly due to weather conditions at drilling and application, says Bayer’s Gordon Anderson-Taylor. The standout year, for all the wrong reasons, was 2011 when a particularly dry autumn resulted in much lower levels of control than is typical.

“In recent autumns there’s been more soil moisture around at drilling time which has enabled pre-ems to function better. Later drilling dates also help as pre-ems are far less likely to be applied to truly dry soils.

Bayer trials show performance of Liberator is variable across seasons, with very poor blackgrass control in the dry autumn of 2011.

“Depending on the season, it’s possible to achieve control of up to 80-90% from Liberator (flufenacet+ diflufenican) alone, but in a very dry season it could be much lower. Last autumn saw late drillings into good moist seedbeds and timely herbicide applications.

“I think a lot of people thought they had initially done a good job but were caught out in the spring when the Beast from the East took hold. Many were quite shocked to see blackgrass heads appearing in June.”

Those that had a clean crop had followed up with a post-em spray, he points out. “If you’re in a difficult blackgrass area, you’re really aiming to achieve 97-98% control and, because the populations are so high, it can be difficult to achieve this with just a pre-em. If the weather, seedbed or timing isn’t right, it’s virtually impossible to achieve those levels of control even if you optimise all these factors,” he stresses.

Clearly the big concern this season is a lack of moisture after a very hot summer and very little rain, factors that may affect establishment and subsequent pre-em herbicide performance. Continued dry weather into Sept and Oct could make a repeat of 2011 possible, so late drilling may be even more important this season, comments Gordon.

Since low moisture reduces pre-em efficacy and high soil temperatures also increase the rate at which residual products break down – both are obvious risks this season until there is significant cooler, wetter weather, he highlights.

Although Mother Nature has done the subsoiling this year, soils which have cracked deeply may benefit from a light cultivation to fill in the cracks.Sprayer operator and farmer Iain Robertson has seen a noticeable difference in success rates from his pre-ems throughout the seasons, which he too has put down to soil moisture.

“We always try to apply Liberator as close to drilling as we possibly can, firstly to make use of conserved moisture and secondly because this is when the actives are at their closest to the weeds’ rooting zone. As they grow their roots will move away from the herbicide.

“We also don’t use generic products very often – it’s the difference between Coca Cola and own brand Coke. The R&D that goes into Liberator compared to a generic is vast and all the little goodies that you don’t know are in there, like water conditioners and drift retardants, pay huge dividends.”

Despite the dry summer, soil and cultivation specialist Philip Wright thinks there are a lot of positives we can take into the autumn. “On most soils with any clay content we’re seeing some quite large cracks opening up and they go down quite deep. This means that some of the work you would normally try to do with the subsoil won’t be necessary.

“On top of that, the soils have been dry and strong so there’s very little, if any, harvest damage to rectify. So take the opportunity to do as little work to the soil as possible.”

Philip thinks that a very shallow, light cultivation to slightly fill in the cracks may be a real benefit. “Chipping off some small clods into the cracks will create pockets and spaces that will persist even after the soils moisten up and close. As the soils close, material in the gaps will encourage secondary cracks and fissures to form which will really help with soil drainage and structure next season.”

But he emphasises only light and minimal cultivation is advisable and only where absolutely necessary, particularly since blackgrass dormancy is very low. Over-cultivating is likely to lead to moisture loss – something to be avoided this season. Worse still, it could result in the formation of large rock-like clods that are difficult to work, he warns.

“Some blackgrass seed may get knocked down the cracks, but this is will end up far enough away from the surface to stop it causing problems,” he adds.

The big question is ‘when will soils be moist enough to drill?’ It’s not a straightforward answer because there are a number of influencing factors, including the soil type, local weather conditions and crop residues. Anything left on the surface is likely to be a plus this season to keep some moisture in the soil, notes Philip.

The thing to watch out for is drilling when there’s only a little bit of moisture about from recent rainfall and then it becomes dry again. “This could be enough to get germination started, but the plant’s roots will be looking for water in soils which quickly become dry again and this could lead to crop failures.”

Philip anticipates that most winter cereals are less of a concern than oilseed rape. The shift to later drilling means that cereals should go in after rainfall and shorter days will allow moisture levels to build up sufficiently to keep crops going. But until that prolonged period of rain, farmers are well advised to hold off cereal drilling and herbicides to avoid a repeat of 2011.

New data shows not all flufenacet performs the same

An autumn treatment of a flufenacet-based pre-em herbicide has long been recommended as the best possible start to a blackgrass control programme, but the choice of products has become wider in recent years with the introduction of generic formulations.

This has left many growers questioning whether seemingly identical products really do differ in performance. Gordon believes they do and has trial evidence to support his view.

“In our trials comparing Liberator with several other co-form products, small but significant differences were observed in both efficacy and persistency,” he explains.

“These showed around 6% greater control from Liberator, together with reduced variability in control from site to site. Such differences in control are likely to be even greater in more challenging seasons.

“I think most people appreciate how it’s the small details that add up when it comes to blackgrass control and this is one of those details – there’s a little more to product performance than just the delivery of active ingredients.”

In the latest trials looking at pre-ems in annual meadow grass, Liberator has been found to have longer lasting residual activity than its generic alternative, with the formulation of the herbicide likely to be responsible for this.

Gordon explains his reasoning behind it. “We’re seeing a difference in efficacy between Liberator and alternative formulations and one reason for this may be related to residual activity. It’s most likely to be related to differences in the loss of active due to the rate it breaks down and/or movement away from the rooting zone.

“Exactly which aspect of the formulation is responsible for the varying efficacy seen has not been determined. It could be related to the particle size of the active, making it more prone to break down in the soil or prone to dissolving, or to the co-formulants or both,” he suggests.

Drift control ‘blindly trumping’ spray performance

Many sprayer operators are unintentionally compromising grassweed control by putting too much emphasis on drift reduction when applying pre-em cereal herbicides. That’s the view of Agrovista’s northern region technical manager Chris Martin.

He believes the increasing use of air-induction and low-drift nozzles contradicts decades of work that clearly shows maximising the number of droplets is the key to optimum results. “Whilst reducing spray drift will always be vitally important, an industry obsession of drift control is in danger of blindly trumping spray performance,” says Chris.

“Using these nozzles in every situation is doing the opposite of what we need to achieve – it’s a bit like throwing beach balls out of the nozzle rather than marbles. We need to paint the soil as evenly as possible, and the more droplets we can produce, the more effectively we can do that.”

A medium spray quality of 200 microns will produce eight times as many droplets as a coarse, 400 microns spray at the same water volume, and a fine spray of 100 microns, 64 times as many.

“That’s all well and good in theory, but finer sprays are a lot more drifty. We can’t be too prescriptive – we’ll very probably need to compromise, choosing the option that produces the best spray quality without causing excessive drift in the field on a particular day, while maintaining an adequate forward speed.”

Higher water volumes also have a direct effect on droplet numbers, and years of Agrovista trials show that 300 l/ha using a medium to fine spray quality produces the best results.

“It might not suit everyone, but I truly believe in bad grassweed situations, we need to get as close to that as we can,” says Chris.

Other things being equal, increasing volume requires switching to a larger aperture nozzle. But this will result in a coarser spray pattern, reducing or even negating the benefit. Another approach would be to reduce speed.

“Halving your speed would double the water volume while maintaining droplet size. This would adversely affect work rates but could be an approach on the worst fields.”

For growers geared up to handle large water volumes in tight timeframes, twin lines would be the ultimate, if expensive, solution; enabling high volumes to be sprayed while maintaining forward speed and spray quality.

Twin caps offer an excellent and much cheaper alternative, he suggests, and using blue 03 nozzles at 3 bar at 9.6km/h would deliver about 300 l/ha. “For growers who are reluctant to accept the lower work rate that higher volumes bring, this approach could be used on the worst fields.”

To help keep drift at acceptable levels, boom height is key. Maintaining a distance of 40-50cm above the target is ideal, but can be difficult to achieve on wider booms, particularly as forward speed increases.

Spray application aids can help further. Remix reduces spray drift and produces a more consistent droplet size, by reducing the production of very fine and very coarse droplets, improving spray deposition.

Independent work at Silsoe Spray Applications Unit has shown Remix can also maintain nozzle spray angle for longer when pressure reduces as the sprayer slows at headlands or travels up hill, improving the spray pattern and reducing turbulence under the boom.

A further benefit is that Remix’s molecules are positively charged, helping to bind the herbicide active to clay and organic matter, keeping it in the surface layer for longer to optimise weed control and reduce seedling damage.

“Extensive trials over the past 10 years have shown using Remix increases blackgrass control from a typical pre-em stack by 11%, as much as Avadex typically brings, for a few pounds per ha,” says Chris.

“With pre-em programmes approaching £50/ha, there’s no argument in my mind. I recommend Remix in every case, and especially where low-drift or air-induction nozzles are the default option, where contractors insist on using them or because conditions are marginal and timings might otherwise be missed.

“Drift control is not the issue here, but our trials prove that the additional benefits of Remix can boost the performance of air-induction nozzles close to that of a flat fan.”