Scientists are getting closer to discovering the origins of blackleg infection in potato seed crops. CPM finds out the latest research findings and how Scottish seed growers are acting on them.

If blackleg gets in at the start of a five to six-year multiplication process then the levels of infection will increase year on year.

By Lucy de la Pasture

Over the past few seasons, blackleg has been the thorn in the side of Scottish seed producers, who otherwise are producing seed of the highest quality. In recent years, levels of blackleg have mysteriously begun to increase, with the disease now the number one reason for down-grading or failure of seed stocks.

The inevitable question is ‘why is this happening?’, says Prof Ian Toth, research theme leader at the James Hutton Institute. To try and understand the issue, AHDB Potatoes and SASA jointly funded a three-year project to identify the routes of blackleg contamination.

“We’re trying to understand how contamination gets into a high-grade seed crop in the first place,” he explains. “It’s important because if blackleg gets in at the start of a five to six-year multiplication process then the levels of infection will increase year on year.

“So we’ve been looking at first and second generation seed crops and trials and have found that even mini-tubers, which were clean to the best of our diagnostic knowledge, showed a build-up of bacterial contamination on the roots and stem bases as the season progressed,” he explains.

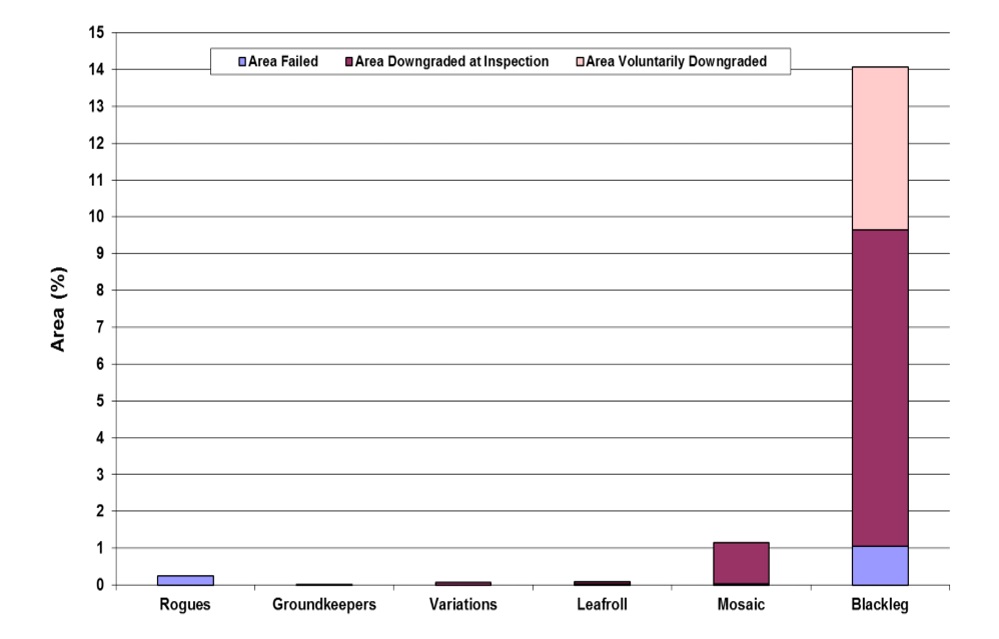

Seed area downgraded and failed

Blackleg is by far the biggest problem for potato seed growers Source: SASA Growing Crop Inspection, 2016 (figs expressed as a percentage of seed area entered for inspection

The point where levels of the bacteria responsible for blackleg, Pectobacterium atrosepticum (Pba), reached their highest levels coincided with haulm desiccation, which indicated that the method of haulm destruction may have a critical bearing on the potential levels of blackleg infection, he says. This is an observation that fitted in well with many seed growers’ observation that blackleg had become an increasing problem since sulphuric acid was withdrawn from use.

Currently it’s unclear whether contamination occurs ‘naturally’ from the environment, from neighbouring crops or by machinery/handling.

Although the exact origin of the bacteria that causes blackleg hasn’t yet been pinpointed, they get into the soil and appear to multiply on plant roots.

“The exact origin of the bacteria hasn’t yet been pinpointed,” admits Ian Toth. “But they get into the soil and appear to multiply on plant roots, which provide a nutrient-rich environment for them.”

Perhaps the good news for growers is that there hasn’t been a shift in the population of Pba, so while the Pba populations remains diverse, the increase in blackleg isn’t due to a new strain, he explains.

“When first and second generation seed is planted into fields close to lower grade crops which have some blackleg present, there’s evidence that you get movement of the bacteria into the high-grade crops. That’s why it’s very important not to plant high-grade seed in proximity to other potato crops,” he says.

The study showed that Pba appears to enter through the canopy and roots as well as via seed tubers. Damage to plants increased entry and spread of Pba, though some varieties were more susceptible to entry without damage, explains Ian Toth.

The discovery that blackleg can develop through the contamination of roots and doesn’t require a contaminated seed tuber means that even very high quality seed is at risk from picking up infection during the same season. It may be one of the reasons that diagnostics on seed doesn’t always give a reliable indication of future blackleg, suggests Ian Toth, though he’s quick to point out the value of diagnostics.

“Diagnostics remains a very important tool. In the UK, we’ve previously just tested lenticels for bacterial contamination but we’re now finding we need to test the stolon end of the tuber as well to improve the quality of diagnostic testing,” he adds.

Rapid Haulm destruction is critical for blackleg control.

Another recent finding is strong evidence of clustering (critical distance 15km), with the location of blackleg clusters varying from year to year. The study of blackleg distribution around Scotland was made using the SPUDS database, derived from Science and Advice for Scottish Agriculture (SASA) seed inspections.

“This tells us that the presence of blackleg in one field is directly related to its presence in other fields but also confirms that fields or regions don’t have an inherent problem with blackleg because the clusters move each year.”

What’s behind this clustering effect isn’t clear and needs to be looked in to, believes Ian Toth. “The clustering may be due to microclimate but we’re not sure. We need to find the cause because it’s potentially very useful information that could help reduce the blackleg issue in Scotland by enabling growers to target control measures,” he suggests.

Eric Anderson, senior agronomist for Scottish Agronomy, has long held the belief that speed of haulm death is of critical importance when it comes to minimising contamination by blackleg on the stem base but also other pathogens, such as phoma which causes gangrene in store.

“We’ve been looking at desiccation techniques for several years, to learn how to use them better in the absence of sulphuric acid,” he explains. And to that end, he’s been helping two Aberdeenshire seed growers with their own commercial trials in pre-basic seed crops.

Jim Reid grows seed for McCain and decided long ago that sulphuric acid wasn’t an environmentally acceptable method of desiccation, opting for diquat (as in Reglone) as his desiccant of choice in 2002.

“In 2002 we split a field and applied sulphuric acid to one half and diquat to the other. It was a eureka moment when the diquat did a better job than the acid and we’ve never used acid again,” he recalls.

That’s not to say desiccation is a simple job – it’s anything but, believes Jim Reid. “Diquat needs ultra-violet light to activate it and when it comes to desiccation, every season is different so there’s no blueprint. Growing potatoes is all about attention to detail and that includes burning them down. You need to have a feel for it.

“Climatic conditions before T1 and between T1 and T2 are important when it comes to deciding which desiccation regime to follow,” he notes.

But one thing that has come out of the work Jim Reid, Scottish Agronomy and McCain have been doing is that it’s critical to get the water volume and spray quality right to achieve a good, rapid defoliation of the crop.

“We recognised that the target shape of the potato plant is very different to a cereal plant. Potatoes are a broad-leaved structure with interlocking horizontal leaves, creating a closed canopy. The leaves are good collectors of vertically moving spray but only in the upper canopy. Boom height and sprayer forward speed are also critical,” explains Eric Anderson.

Persuading the spray into that canopy is tricky – often only 10-15% of the T1 spray ends up where it’s needed, at the stem base. So, it’s important to understand the behaviour of droplets of different sizes in terms of deposition and coverage on the crop canopy, stresses Eric Anderson.

“Spray parameters shouldn’t be expected to perform similarly in all canopy types and should be modified to the most effective delivery of the spray to the target treatment zones. For example, using air-induction (AI) nozzles increases droplet size and momentum that assists in the coverage of lower canopy and stem.

“Increasing the height of the boom from 0.5m to 1.0 m increases drift by a factor of more than five. For a given boom height, the risk of drift can be reduced by reducing the spray angle of the nozzle. Using a narrower spray angle together with an AI nozzle would reduce drift by between 35-47% at nozzle heights above the crop of 0.9m and 1.1m.

“Furthermore, at a constant sprayer pressure, decreasing sprayer forward speed decreases the risk of air being forced over the boom which in turn generates a low-pressure zone (vortex) and sucks small droplets upwards,” he adds.

“Getting penetration to the mid-lower canopy is very important when burning down potatoes. The consequence of pathogens on the stem base, such as blackleg and phoma, is related to the speed of kill, so if defoliation is inefficient, then speed of kill will be slow and pathogens have an ideal home to proliferate.”

One of the problems Eric Anderson points out is the lack of guidance on nozzle technology in potatoes when compared to cereals and oilseed rape, where a lot more work has been done. “That’s why it’s important to be carrying out this work in a commercial situation where a crop sprayer is used rather than the knapsack sprayer which is used in smaller plot trials,” he believes, adding that angled nozzles are giving the best results on-farm.

“The widespread belief that a fine spray gives better penetration is wrong, a medium spray is better for desiccation. When the size of spray droplets is reduced, their numbers increase, and the potential for off-target droplets also increases. Reducing droplet diameter by half multiplies the number of droplets by eight, so it can have a big effect.

The formulation of sprays has an additional effect. Emusifiable concentrate and emulsion in water formulations reduce the number of drift-prone fines by a factor of two, he says.

Water volume is also crucial when it comes to getting quick defoliation, with 400 l/ha a must at the T1 timing. “At the second treatment timing (T2) the water volume can be in the range 200-400 l/ha. It depends on the crop canopy and generally the more indeterminate varieties will need a higher volume at T2,” he explains.

One of the significant findings that Eric Anderson and Jim Reid have made in their comparisons is that there are discernible differences between systems of desiccation and the level of blackleg in crops when the seed is grown on the following year. It’s a fact that ties in with the research being undertaken by Ian Toth and colleagues, who report levels of Pba becoming an issue right at the point of haulm destruction.

That means planting back daughter tubers in the subsequent year is the only way to discern differences in desiccation treatments because blackleg doesn’t necessarily show up in the same growing season as its planted. Harvested tubers are stored and planted back into 0.2ha plots and in 2016 there were 14 different treatments.

This is echoed by Ian Toth’s research where across all PB1 trials, between 20 and 70% of harvested plants had contaminated tubers, depending on the variety or year of sampling. Most contaminated tubers were harvested from symptom-free plants.

“The fact that our field comparisons aren’t replicated has been criticised but we believe that it’s important that the plots are planted, sprayed and harvested using commercial equipment so it’s representative of farm practice.

“In 0.2ha we plant 12,000 tubers compared with 90-100 on a conventional small plot trial with 3.6 x 6m plots, where it’s not possible to differentiate any less than 1% differences. With 12,000 tubers, we’ve a much higher level of resolution than in the small plot trials,” explains Eric Anderson.

So how can growers achieve rapid burn-down using desiccants? Being aware that no single desiccation decision is more important than the next one is a good starting point, says Eric Anderson.

“Using the right product at the right timing, with the right interval between application with the aim of rapid and complete desiccation is crucial for blackleg control,” he says, adding that a 6-7 day interval is usually best.

“Because the speed of diquat activity is affected by ultra violet (UV) light levels, adding additional products at T2 gives more reliable control under dull conditions. Typically, adding 0.5 l/ha Spotlight Plus (carfentrazone), to 2.5 l/ha diquat will increase the activity on the stem and act as a penetrant for the diquat because of its micro-emulsion formulation,” he explains.

Unlike last year, UV light wasn’t a limiting factor at the desiccation timing this autumn, says Jim Reid. “We applied diquat at T1 and followed by diquat plus carfentrazone at T2. The purpose of the T1 spray is to defoliate the leaves to expose the stems and some growers use a flail to achieve this. Personally, I’d never use a flail in a seed crop, partly because of blackleg and partly because of the shock it causes to the crop, occasionally resulting in vascular staining.”

Eric Anderson agrees that flailing isn’t a good option for the first three generations of seed (pre-basic) where there’s a nil tolerance for blackleg. Field generations 4, 5 and 6 have a small tolerance for blackleg and if flailed, he prefers to use diquat as a pre-treatment.

“Where diquat isn’t used as a pre-treatment then blackleg is frequently higher in subsequently planted tubers. Flailing will have got rid of nearly all the leaves, leaving the odd hanging leaf and stems so a follow up using 1 l/ha diquat plus 1 l/ha carfentrazone should be adequate to take off the last bit of leaf and deal with the stems,” he says.

Another interesting observation from their work has been that the choice of blight fungicide applied with the diquat appears to affect the amount of blackleg in the subsequent crop.

“We observed over the past two seasons that where Ranman Top (cyazofamid) is tank-mixed with diquat, there’s more blackleg in planted back seed than where Shirlan (fluazinam) is used. It’s something we’re going to look closely at and suspect it has something to do with the wetting systems of the different blight sprays,” he reckons.

Another Aberdeenshire grower is approaching blackleg control in his pre-basic seed in a totally different way. With around 100ha of seed in his care, from first generation mini-tubers and the multiplying generations beyond, Jim Cruickshank sees it as his job to delay the build-up of disease which starts right from the first generation.

“Every haulm-disposal system has risks but in my mind, it has to be most efficient to completely remove the haulm. We’ve been pulling haulm by hand to try to assess whether this approach can work,” he explains.

With 3-4ha of first generation mini-tubers in the ground, his team of hand-pullers covered about 1ha of the more disease-prone varieties this year but the aim is to hand pull the haulm from all the first-generation seed next season.

“We’ve learned more this year because we had blackleg pressure early in the growing season. Where we’d hand pulled the haulm even the very sensitive varieties were clean,” he says. “It’s an observational conclusion but hand pulling does seem to stack up even though it’s expensive.”

At a cost of around £1500/ha for haulm pulling it’s not an option on a large scale, says Eric Anderson.

“But to put it into context, a first-generation seed grower will have about 50,000 mini-tubers in 1ha at a cost of 40-45 pence per tuber. That’s a lot of money invested. Hand pulling costs 3p per tuber planted, so if it minimises blackleg then it’s well worth doing.”