The painful bit about making an arable system run smarter is having to log and document every job. In the third of our series on data management pioneers, CPM tells the story of Telematics, that does it all for you.

There was a farm spending three and a half days over the harvest period just waiting for trailers.

By Charlotte Cunningham

It’s no secret that unpredictable weather patterns dictate harvest every year – during this time, a farmer’s focus can easily shift from doing things efficiently to just getting the job done as quickly as possible.

However, reduced efficiencies put pressure on both time and cost. So is there a solution which allows farmers to maximise their productivity without increasing their work load during the busy harvest period?

Claas believes it’s found the answer with its revolutionary software, Telematics. This data-logging system is available on all harvesting machines and tractors, helping farmers analyse and optimise work processes on farm – effectively cutting the amount of time spent carrying out operations.

Edward Miller noted there was an opportunity for farmers to use data gathered to look at how much time machines were spending carrying out the actual operation.

Telematics records information from more than 200 parameters – including operating conditions, performance data and Geodata (GPS tracking) – and automatically transmits to it to the Telematics web server. With an Automatic Documentation license, drivers can simply enter a field to carry out work and the system automatically creates a job. When required, this job or jobs can then be downloaded and imported on to farm management software.

While the fundamental principle of increasing efficiency has remained throughout the Telematics journey, its purpose and functionality has changed rapidly since its birth 13 years ago.

“Telematics reared its head in 2004, originally as a collection of data-logging files for research and development,” explains Edward Miller, product manager at Claas UK. “The data was initially being used to monitor performance of prototype machines in the UK and Europe.”

The information was sent over to the UK and analysed by the team at Claas UK who realised it could be used to benefit customers, leading them to dig deeper into collecting information about in-field efficiencies, says Edward. “There was an opportunity to look at how much time machines were spending carrying out the actual operation, idling on the headlands and waiting for trailers,” he recalls. “This led us to look at what customers were able to save in terms of time by optimising the harvest process – while we can sell a bigger and better combine, we can’t sell more time.”

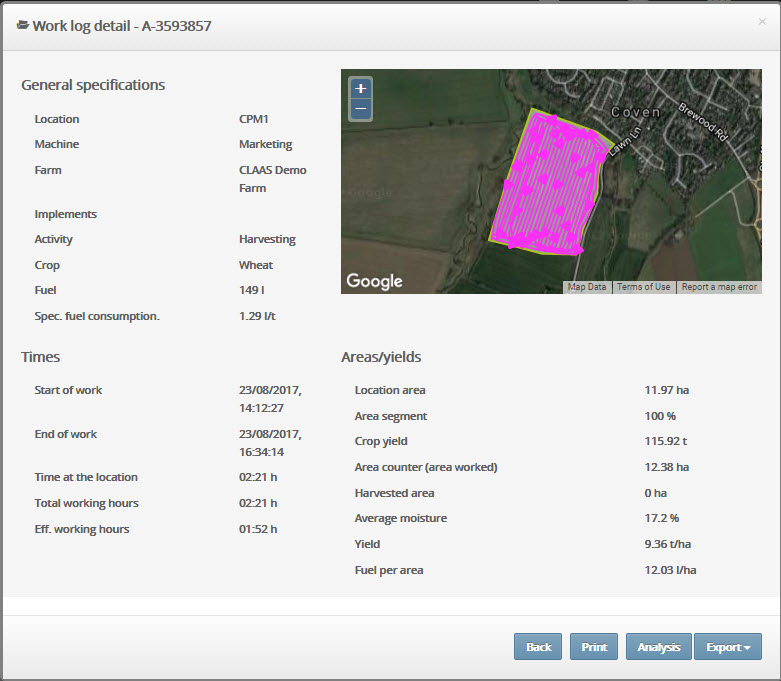

All of the data from the field for a job is gathered automatically and summarised on the web page.

Telematics was initially offered solely on combines, then foragers a year later. The following year also saw birth of the Telematics website, which allowed users to log in and access all their machine and performance data in a visual format. “Customers were able to physically measure how much time was being wasted – many were astounded,” explains Edward. “In one particular case, there was a farm spending three and a half days over the harvest period – based on a 10-hour day – just waiting for trailers.”

Eight years on, 2012 saw a wind of change come through the system, but what sparked the progression of Telematics into the version available today? When Telematics was first developed, the focus was on machine settings and efficiency – however, Claas found the usefulness of this data only had a three-year validity.

“The issue was that in the first year of using it, customers were able to identify the problem, in the second year they were able to fix it and by the third year they were working efficiently,” explains Edward. “While it did fundamentally change the way farmers worked during harvest, they couldn’t see any further benefits of investing in the system.

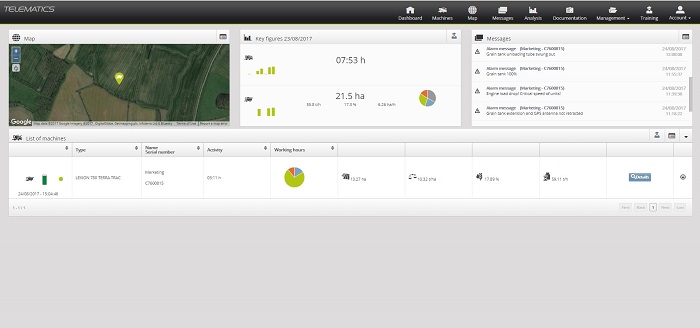

The dashboard where the customer sees all the main machine info at a glance.

“This forced us to look at what else we could do with it. We recognised that growers are increasingly required to record every operation they carry out – from harvesting to spraying – which led to the development of the automatic documentation feature in 2012.”

The initial feedback was extremely positive, with customers particularly enthusiastic about how easy it made recording of information. Today, around 90% of Claas machines, that offer yield mapping, use automatic documentation – with 600 machines running the Telematics system every day in the UK, and a standard feature on all Lexicon and Tucano combines and Jaguar forage harvesters.

“We always knew customers wanted a better way to transfer and record data, rather than using the old chip card system,” says Edward. “Automatic documentation transformed Telematics’ uptake – it’s a tool that can be used every day.”

Of course, no new technology comes without its challenges. Despite always believing Telematics was a winning product, Claas had initially battled to get customers to adopt the system. “Our biggest challenge was the ‘Big Brother’ issue,” he notes. “A lot of drivers were suspicious they were being spied on by Claas – mainly due to a lack of understanding as to how the system actually worked.”

To overcome this, Claas spent time running post-harvest workshops and providing training to educate customers. “We looked at how farmers could do better, based on the data available, and explored the future, taking into account customers’ ideas about how we could take the system forward. Once there was a greater level of understanding, farmers realised how beneficial Telematics could be.”

Fleet View allows combine operators to track how far away the trailer is, and trailer drivers to see how full and how fast the combine is going.

With so much data collected, using Telematics could be quite daunting, so keeping the system as simple and usable as possible was key, says Edward. “The website was redesigned in 2012 – aimed more at the customer – and the switch to an open format of data meant that any modern farm management software could read the data collected.”

Telematics has been particularly beneficial for large scale farmers and contractors thanks to automatic documentation reducing the pressures of record keeping. “Traditionally, contractors are so busy around harvest time that it often takes them months to produce an invoice from a notebook sat in a combine or forager. The beauty of Telematics is that by the time the driver leaves the farm, the job information could already have been downloaded and an invoice is ready to be produced and sent out.”

And it’s not just farmers benefiting from Telematics. For Steve Gillett, service manager at Claas Eastern, the system is crucial for diagnosing machinery problems. “I use Telematics every morning to locate and find errors in a machine,” he explains. “For example, if there’s a problem with the mapping function, I can dial into the machine and find exactly which field the error is in. I also use it to see when services are due, which is very useful for forward planning.”

The ability to diagnose and manage jobs before even reaching the machine helps save time and cost for both customers and technicians. “Customers are often shocked at how quickly and efficiently we can deal with machinery faults,” says Steve. “Technicians know exactly what problem they’re going to work on, which has a big impact on keeping downtime to a minimum for everyone involved.”

So, what does the future hold for Telematics? Next on the agenda is the introduction of Fleet View. “This will be a tool based on harvest logistics,” explains Edward Miller. “Users will be able to see, via an iPad, where the all the machines and equipment are; effectively like a tracking system.”

This will be a beneficial feature for both combine and trailer drivers, he adds. “Combine operators will be able to track how far away the trailer is, freeing up time for things like vehicle maintenance, and trailer drivers will be able to see how full and how fast the combine is going and where exactly in the field it is – it takes the guesswork out of it.”

Data collection seems to be a growing culture in modern day agriculture, but knowing how to utilise it is key. “We’re at a point in time where more and more data is being captured, but farmers just don’t know what to do with it,” says Edward. “The main feedback we get from our customers is just how much time is being saved by having this data in a simple format through having Telematics.

“For us, it’s most rewarding when we’ve helped a customer who has had a challenging harvest to see just how much time they can save. It’s our job as an industry to provide the required data without creating more work for farmers – we need to deliver solutions, not products.”

Yield mapping drives the data revolution

Yield mapping has been a core feature of Telematics since its birth. To help support functionality, Claas sought the expertise of precision farming service provider, Soyl. The firm produces recommendations for around one million ha every year, taking into account all aspects of precision farming – from variable rate nutrition to variable rate seed.

“We’ve been involved with yield mapping right from the start,” recalls Tom Parker, head of products and technology at Soyl. “We offer a support mechanism for yield mapping, helping with the installation and set-up, as well as how it might integrate with farm software. There’s 24-hour support for any challenges that come up along the way.”

While some farmers have been collecting yield data for a long time, it’s only now that the true value of this information has been brought to light. “Yield data has a long life of value and allows farmers to draw business insight,” explains Tom. “Even if you’re not sure how to use it just yet, it’s important to collect yield information – one thing you can’t do is record previous data.”

From a management perspective, access to this precise level of data helps farmers make better-informed decisions, says Tom. “It helps growers understand variability,” he explains. “Yield is a snapshot of a crop’s performance at one point in time, but building data over multiple years helps to identify performance. This brings into sharp focus which areas of the farm are most profitable for crop production.”

It also enables farmers to look at the bigger picture – such as relationships between performance and soil type, and how inputs can be optimised.

In addition, identifying low yielding areas can influence future decision making to ensure every ha of the farm is profitable, says Richard Tait, area manager at Soyl. “Where there are consistent areas of low performance, farmers should be considering whether they could use these areas to deliver value via stewardship schemes or EFAs instead,” he adds. “In effect, maximising crop production in high output areas and using those with lower performance to improve biodiversity.”

Tasks tracked without the toil

A self-professed Telematics sceptic in the early days, arable farmer Edward White is now using the system to manage both his home farm and contract farming business. “The initial version of Telematics wasn’t very user friendly and it told us what we already knew,” he recalls. “The introduction of automatic documentation was a huge leap forward.”

With 1416ha of in-hand and contract farmed land in Wilts, Edward finds Telematics a very useful tool for improving accuracy during busy periods. “We do a lot of contract farming and the information collected is downloaded automatically to our farm software,” he explains. “Being able to accurately measure the field sizes is very helpful.”

While machinery choice ultimately boils down to performance, having Telematics as an added extra has helped relieve pressure during the busy harvest period. “It’s taken a lot of hassle off the combine driver in terms of managing both the fieldwork and the paperwork,” says Edward. “There’s often pressure to get going and started on new fields – being able to drive straight into a field makes it much easier.”

Ultimately, increased efficiency has resulted in both time and cost savings, he says. “There’s a big saving in time – particularly in small fields. Data saves automatically so in the winter you can go back and look at how productive the harvest has been. I’ve also found it particularly beneficial for end-of-year discussions with our landlord – having the data there makes everything much more reliable.”

Innovation Insight

CPM would like to thank Claas for kindly sponsoring this article, and for providing privileged access to staff and material used to help put the article together.